Bursting strength testing is an essential procedure in the quality control process of various materials, particularly in the textile and packaging industries. This test method determines the ability of a fabric, paper, or board to withstand pressure without rupturing. The standard procedures such as ASTM D 3786-01, ASTM D 3786 – 80A, and ISO 1060 PART-1 1987 provide guidelines to conduct these tests with accuracy and repeatability.

Bursting strength testing is an essential procedure in the quality control process of various materials, particularly in the textile and packaging industries. This test method determines the ability of a fabric, paper, or board to withstand pressure without rupturing. The standard procedures such as ASTM D 3786-01, ASTM D 3786 – 80A, and ISO 1060 PART-1 1987 provide guidelines to conduct these tests with accuracy and repeatability.

- Importance of Burst Strength Testing

The bursting strength of a material is a vital parameter that manufacturers must not overlook. It reflects the material's ability to hold up under extreme conditions, which is crucial for ensuring the safety and durability of the final product. For example, in the packaging industry, the bursting strength indicates the ability of the box to withstand external pressures during shipping and handling, ensuring that the contents are protected.

- ASTM Standards for Bursting Strength Testing

- ASTM D 3786-01: This standard outlines the procedure for testing the bursting strength of knitted fabrics and nonwoven materials. It specifies using a hydraulic or pneumatic diaphragm bursting tester to apply a force on a fabric specimen until it bursts. The result is expressed in pounds per square inch (psi).

- ASTM D 3786 – 80A: This older version of the standard also covers the bursting strength of textiles. While it has been largely replaced by more recent versions, it still serves as a reference point for historical data and comparative studies in textile engineering.

- ISO Standard for Bursting Strength Testing

- ISO 1060 PART-1 1987: This part of ISO 1060 focuses on the bursting strength of paper and board using hydraulic or pneumatic burst testers. The standard is critical for ensuring the quality of paper products, including how they will perform under stress during use, such as in packaging applications.

The Role of Bursting Strength Testers

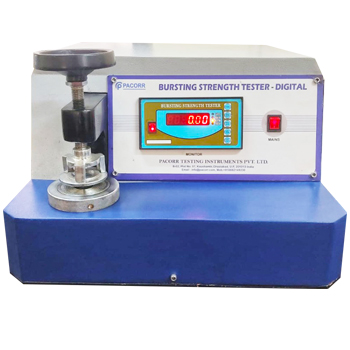

A bursting strength tester, such as those provided by Pacorr, plays a crucial role in these assessments. These devices are designed to simulate the conditions under which materials like textiles and paper products might fail when subjected to increasing pressure. By understanding these limits, manufacturers can enhance their product designs, choose better materials, and improve overall product performance.

Pacorr's instruments are built with precision engineering to comply with international standards. Their range of bursting strength testers offers features that allow for easy integration into existing quality control workflows, with accurate and reliable results that help maintain high standards of product quality.

The importance of adhering to established standards like ASTM D 3786-01, ASTM D 3786 – 80A, and ISO 1060 PART-1 1987 in bursting strength testing cannot be overstated. They provide a benchmark that manufacturers can rely on to ensure their products are durable, safe, and capable of meeting consumer demands. Companies like Pacorr are at the forefront of supplying the industry with reliable testing equipment that ensures compliance with these critical standards.