Ensure Best Look and Feel of Your Products with Stronger Packaging Labels

Labels and packaging has many different roles to play for a product and its brand. One of the major tasks of packaging is to protect the products from any external impacts and preserve its safety. Another task of packaging is to give a better look and feel to the products. It is well known fact that the look and feel of a product has a great impact on the customer’s mind and how they perceive the quality of the products. There are higher chances for customers to choose a product that has a packaging with better look and feel. This is why the manufacturers have to focus on ensuring that the packaging they are using for their products has a good look and feel so that it conveys a better quality of product to the customers (Scuff Tester).

Labels and packaging has many different roles to play for a product and its brand. One of the major tasks of packaging is to protect the products from any external impacts and preserve its safety. Another task of packaging is to give a better look and feel to the products. It is well known fact that the look and feel of a product has a great impact on the customer’s mind and how they perceive the quality of the products. There are higher chances for customers to choose a product that has a packaging with better look and feel. This is why the manufacturers have to focus on ensuring that the packaging they are using for their products has a good look and feel so that it conveys a better quality of product to the customers (Scuff Tester).

When the products are being transported or stored, there are high chances that the packaging of the products will be rubbed against other product packaging. This causes the scuffing of the surface of the packaging labels and containers. This scuffing can deface and even deform the look and feel of the packaging and hence can impact the quality of perception of the products lowering its brand value. In addition to that, many times the packaging containers and labels are used for printing important information on them. IF the scuffing is too extensive then this information can be lost due to that and the consumer will not get that information. To avoid this, the manufacturers of packaging materials need to ensure that they test the scuff resistance of the material to assure that they will be able to survive such extensive scuffing during their usage.

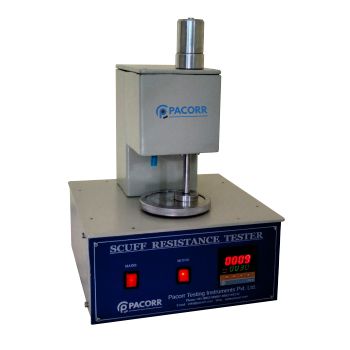

For this, they need a testing instrument called scuff resistance tester. This instrument is prescribed by the international testing standards for testing any material for scuff resistance. The instrument simulates the actual rubbing or scuffing conditions using two same types of labels that have a relative motion against each other. The two specimens are rotated on each other for a specific number of rotations and then taken out. After that, they are analysed for the damage the rotations have incurred on them. This helps in studying the extent of deformation and defacing that the specimen can bear during transportation and storage handling. The scuff resistance tester offers the best way to test the quality as well as the scuff resistance of the packaging materials and labels to ensure the best look and feel of the products.