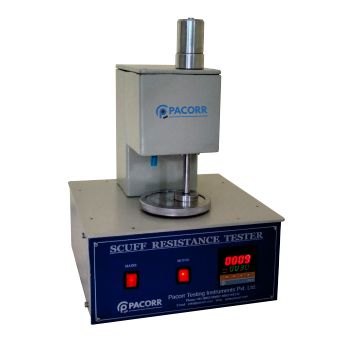

Ensure Coated Materials Scratch Safe by Using Scuff Resistance Tester

The strength of printed, painted, or coated information and labels to oppose scrubbing activities can be imitated by a scuff resistance tester. These methods can re-enact the effects of rubbing by contact with humans, things, or materials utilizing the usage of scuffing methods and related quality control tester. Clarity of names is important on drug and electronic appliances. The durability of printed information on keypads can be controlled by a practically identical method. Name clarity is important on drug and medical devices and is consistently detected by techniques, for example, a Rub resistance test procedure. Scuff Tester can determine the quality of printed or coated material on numerous surfaces. Therefore, it is important to conduct the test for quality control.

The strength of printed, painted, or coated information and labels to oppose scrubbing activities can be imitated by a scuff resistance tester. These methods can re-enact the effects of rubbing by contact with humans, things, or materials utilizing the usage of scuffing methods and related quality control tester. Clarity of names is important on drug and electronic appliances. The durability of printed information on keypads can be controlled by a practically identical method. Name clarity is important on drug and medical devices and is consistently detected by techniques, for example, a Rub resistance test procedure. Scuff Tester can determine the quality of printed or coated material on numerous surfaces. Therefore, it is important to conduct the test for quality control.

While in transit, the packages are exposed to rub with each other and make a scratch. Scratch-safe packaging is an ideal method to ensure fragile products are unprotected from scratching or scratching during transit. The painted products or those created utilizing glass, plastic, or flexible, scratch-safe packaging includes a fragile non-rough liner on ridged board, which safeguards products from damages in the store network.

Scuffing is a major problem that emerges with packaging materials like cardboard, papers, and corrugated boards. When the packaging of products scoured against an abrasive surface or any rough surface, the material gets damaged, and this can harm the appearance of the labels. Besides, when the material starts to erode, it will lower the quality and the strength of the bundling materials.

The packaging industry is the growing necessities of the packaging things in each generation vertical to profitably store and ship the products starting with one place then onto the next. The packaging materials are used to secure the products used to give a personality to the content inside by providing essential information concerning the products which incorporates the date, coding, and printing of the packaging material.

To measure the behaviour of the label, the test can be speeded up. It subjects the test sample to constant scuffing and results are noticed visually. The behaviour of the printed film after 500 revolutions is noticed. Just set the number of turns, the machine would finish the test in couple of hours. This test fast forwards the frictional impact on the test sample.

Scuff Resistance Tester is highly reliable and gives accurate results with low maintenance cost. The instrument is designed as per ASTM standards. The digital display gives the actual number of strokes applied on the test samples which helps manufacturers to determine the exact number of strokes where the materials can get defaced.