Get the Best Quality Products with Thorough and Precise Quality Inspection

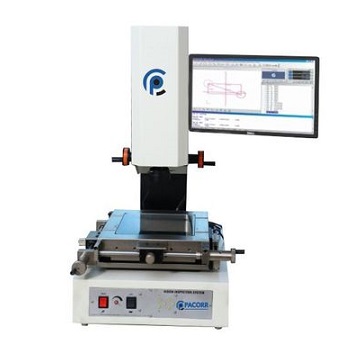

A Profile Projector is known as Optical Comparator that is used for measuring systems which are categorized under the Industrial Metrology Systems. The versatile measuring system in the manufacturing sector where small parts two-dimensional measurements are required in the R&D, Production or Quality control departments. Automotive parts, plastic and rubber parts, wire and cable, biomedical equipment are some of the manufacturing industries which extensively use profile projectors for day to day measurements.

A Profile Projector is known as Optical Comparator that is used for measuring systems which are categorized under the Industrial Metrology Systems. The versatile measuring system in the manufacturing sector where small parts two-dimensional measurements are required in the R&D, Production or Quality control departments. Automotive parts, plastic and rubber parts, wire and cable, biomedical equipment are some of the manufacturing industries which extensively use profile projectors for day to day measurements.

Profile Projector is a useful item in a small parts machine shop or production line for the quality control inspection team. The projector magnifies the profile of the sample material, and projects on the built-in projection screen. The grid on this screencan be rotated to 360 degrees so the X-Y axis of the screen can be aligned with a straight edge of the machined part to measure. This projection screen shows the profile of the sample and is magnified for better ease of calculating linear measurements. An edge of the sample to evaluate may be lined up with the grid on the screen. From there, simple measurements may be taken for distances to other points. This is being done on a magnified profile of the specimen. It can be simpler as well as reduce errors by measuring on the magnified projection screen of a profile projector.

Uses of Profile Projector

Hardness's comparator, intended for the routine inspection of machined parts, was a natural next step in the era during which applied science became widely integrated into industrial production.

Wide uses of instruments such as inspecting and comparing minute parts that are crucial in the system’s structure, as an application quality.

Benefits

Profile Projectors are used to disclose imperfections such as burrs, scratches, indentations or undesirable chamfers which micrometers or calipers can’t reveal.

Used for measuring 2D faces, complex-shape stampings, gears, cams, threads and comparing the measured contour model. Unlike micrometers and Calipers, which measure one dimension at a time, where comparators measure length and width simultaneously.

Optical comparators save time. Ease-of-use factors and ergonomic designs reduce the inspection time, retraining costs and operator fatigue, all while increasing throughput.

Dimensioning techniques designed to give more leeway to parts with their true functional purpose, such as profile tolerance and true-position tolerance with bonuses, reduce the reject rate of good parts that might have passed had their tolerances been assigned differently.

Manufacturers test the quality of minute sample materials using this profile projector so that they ensure better quality to its customers.