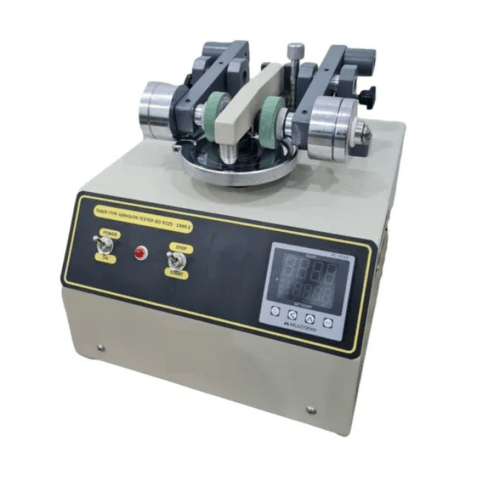

The Pacorr Taber Abrasion Tester is engineered to deliver precise and reliable abrasion resistance testing for a wide range of materials. Built on a durable metallic base and integrated with advanced features, this instrument is specifically designed to measure the wear performance of surfaces subjected to rotating abrasive wheels. Its robust construction, user-friendly controls, and compliance with ISO:9352 standards make it an essential tool for quality assurance in industries such as coatings, plastics, textiles, and automotive components.

- Shipping Area: All over the world

- Model: PCTAT-2.0

Specification:

- Test Specimen Support Disc Minimum Diameter: 100 mm

- Disc Rotation Speed: 60 ± 10 RPM

- Distance Between Disc and Abrasive Wheel (Center to Center): 19.1 mm

- Abrasive Wheel Thickness: 12.7 ± 0.1 mm

- Disc External Diameter: 51.6 ± 10.1 mm

- Motor: 1 HP, Single Phase, 220 V

- Gearbox: High-quality Worm Reduction Gear Box

- Preset Digital Counter: Four-digit for revolution control

- Vacuum Arrangement: Dual exhaust nozzles for debris removal

- ISO:17076-1: 2020

Feautes:

- Rugged Construction: Built on a heavy-duty metallic base for stability and durability.

- Precision Testing: Test specimen is mounted on a disc backed by dual ball bearings for smooth, accurate rotation.

- Dual Abrasive Wheels: Symmetrical arm setup with freely oscillating abrasive wheels ensures even wear testing.

- User-Friendly Controls: Four-digit digital preset counter allows for easy setting and monitoring of test cycles.

- Advanced Debris Removal: Integrated vacuum system with two exhaust nozzles keeps the wear zone clear for precise results.

- Corrosion-Resistant Finish: All key parts are powder coated, painted, or chrome plated for a long-lasting, maintenance-free lifespan.

- Compliant with International Standards: Fully adheres to ISO:9352 for abrasion resistance testing by abrasive wheels.

- Versatile Applications: Ideal for testing paints, coatings, plastics, textiles, rubber, laminates, and automotive parts.

Overview of Taber Abrasion Tester

When it comes to evaluating the durability and longevity of materials, the Pacorr Taber Abrasion Tester stands out as a highly effective solution. The instrument features a flat test specimen disc that is securely mounted to a precision-driven shaft supported by ball bearings. This disc rotates at a controlled speed, powered by a high-efficiency motor and a worm reduction gearbox to ensure stable and consistent operation.

The abrasion testing process is conducted using two freely oscillating abrasive wheels, each positioned on symmetrical arms. These wheels rotate independently and are supported by their own ball bearings, providing accurate and uniform abrasion across the surface of the test specimen. A digital counter enables users to preset the number of revolutions for each test, ensuring repeatable results and easy operation.

To maintain a clean testing environment, the Pacorr Taber Abrasion Tester includes a built-in vacuum system with dual exhaust nozzles strategically placed above the wear zone. This setup efficiently removes dust and debris generated during testing, thus ensuring accurate measurements and a safer workspace.

All exterior components of the instrument are finished with powder coating, paint, or chrome plating. This not only enhances the tester’s appearance but also provides strong corrosion resistance, supporting long-term, maintenance-free operation.

Related Products

Our Clients

Recent Blogs

Enhance your understanding of testing and precise quality control indistinct applications with our

knowledge based articles coming from top editors of industry leaders.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)