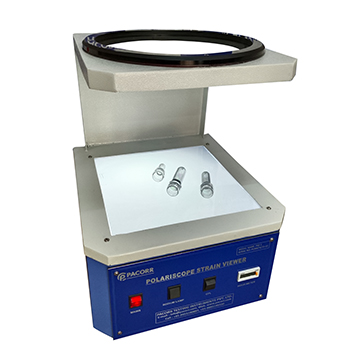

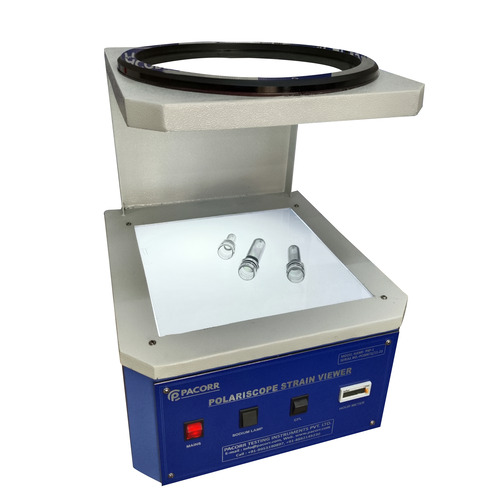

Pacorr presents the Polariscope Strain Viewer – Computerised, an advanced testing instrument designed for precise and accurate analysis of strain patterns in transparent materials like glass and plastics. Recognized for its superior build quality and reliable performance, this computerized Polariscope has become essential for manufacturers and laboratories striving for quality assurance in packaging, bottle manufacturing, PET preforms, glass containers, and optical components.

- Shipping Area: All over the world

- Model: PCPSV-C

A Polariscope Strain Viewer – Computerised is a state-of-the-art device that utilizes polarized light to detect internal stresses, birefringence, and strain patterns in transparent specimens. By digitizing the traditional polariscope setup, Pacorr’s computerized model brings automation, high-resolution imaging, and accurate digital reporting, ensuring objective analysis for quality control teams.

Key Features of Pacorr Polariscope Strain Viewer – Computerised

- High-Resolution Digital Display: Offers clear and detailed visualization of strain patterns for immediate analysis and documentation.

- Automated Image Capture: The computerized system captures, saves, and analyzes images for detailed reporting and quality traceability.

- User-Friendly Interface: Easy-to-operate software allows even new users to perform advanced strain analysis efficiently.

- Adjustable Viewing Area: Accommodates a wide variety of specimen sizes, from small PET preforms to larger glass containers.

- Consistent Illumination: Ensures uniform and shadow-free polarized light, critical for accurate stress identification.

- Data Storage and Reporting: Automatic saving of test results and images for audit trails and compliance documentation.

- Sturdy and Ergonomic Design: Built for heavy industrial use with ergonomic design for operator comfort.

Benefits of Using Polariscope Strain Viewer – Computerised in Quality Control

1. Enhanced Product Safety and Durability

Detecting internal stresses early prevents potential product failures, breakages, and safety issues in the end application.

2. Compliance with International Standards

Pacorr’s computerized Polariscope Strain Viewer helps your business comply with standards such as ASTM C148, ISO 13916, and other global norms for optical strain analysis.

3. Objective and Reliable Results

Digital imaging and automated analysis reduce operator subjectivity, offering highly repeatable and objective results for all types of transparent packaging and components.

4. Increased Productivity

The computerised model speeds up the strain inspection process, allowing quality teams to test more samples in less time without compromising accuracy.

5. Ideal for Multiple Applications

Perfect for PET bottle manufacturers, glass jar producers, optical lens companies, laboratory research, and academic institutions.

How Does Pacorr Polariscope Strain Viewer – Computerised Work?

The device works by passing polarized light through a transparent specimen. When internal stress or strain exists, it alters the polarization, creating visible patterns or colors that are captured and analyzed by the software. With Pacorr’s advanced imaging and measurement algorithms, precise data about the type and location of strain is instantly available.

Why Choose Pacorr for Your Computerised Polariscope Needs?

Pacorr is a recognized leader in quality testing instruments, known for delivering robust, accurate, and user-friendly solutions for the packaging, plastic, and glass industries. Our Polariscope Strain Viewer – Computerised is backed by expert technical support, thorough calibration, and a commitment to innovation.

Technical Specifications – Polariscope Strain Viewer – Computerised

- Display: High-resolution digital screen (customizable sizes available)

- Software: Intuitive PC interface for image capture, analysis, and reporting

- Light Source: Uniform polarized LED illumination for accurate pattern visualization

- Viewing Area: Suitable for a wide range of sample sizes

- Data Output: Image export, PDF reports, audit logs

- Power Supply: Standard AC mains

- Construction: Industrial-grade frame for durability

Industries & Applications

- PET bottle and preform manufacturing

- Glass container production

- Optical lens and component inspection

- Laboratory and R&D quality assurance

- Academic teaching and demonstration

Frequently Asked Questions (FAQs)

Q1: What is the primary use of a Polariscope Strain Viewer – Computerised?

A: It is used to detect and analyze internal stresses in transparent materials like PET, glass, and plastics to ensure product integrity and quality.

Q2: How is the computerized Polariscope better than manual models?

A: The computerized version provides automated analysis, eliminates human error, and generates digital reports for compliance and traceability.

Q3: Can Pacorr’s Polariscope Strain Viewer be integrated into existing quality control systems?

A: Yes, the system can be connected to laboratory PCs and quality management software for streamlined operations.

Q4: Is training required to operate this equipment?

A: Pacorr provides comprehensive training and user manuals, and the intuitive software makes it easy to use even for first-time operators.

Q5: What standards does the Polariscope Strain Viewer – Computerised support?

A: The instrument is designed to comply with ASTM C148, ISO 13916, and similar standards for stress analysis.

Order Your Polariscope Strain Viewer – Computerised from Pacorr Today

Upgrade your quality control lab with Pacorr’s Polariscope Strain Viewer – Computerised. Ensure your products are free from hidden stresses, improve durability, and meet global standards with confidence. For pricing, demo requests, or technical queries, contact Pacorr’s expert team today.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.