Pacorr Box Compression Tester is a robust and highly accurate instrument designed to evaluate the compression strength of packaging materials such as corrugated boxes, cartons, and containers. Built for industries that demand reliable packaging integrity during storage and transportation, this machine helps manufacturers ensure that their boxes can withstand real-world stacking pressures and handling forces.

Whether you are in the business of manufacturing shipping boxes, packaging consumer goods, or exporting fragile items, maintaining packaging strength is critical. This is where Pacorr’s Box Compression Tester plays a vital role in preventing product loss and improving customer satisfaction.

Availability: In Stock

- Shipping Area: All over the world

- Model: PCBCTD

Specification:

- Capacities: 500Kgf, 1000Kgf, 2000Kgf & 3000Kgf

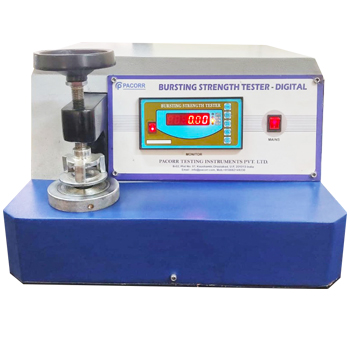

- Display: LCD (Digital) with Backlit

- Accuracy: ± 1% of FSD.

- Least Count: 50gm to 500gm

- Test Platform Size : 600mm x 600mm, 800mm x 800mm, 1000mm x 1000mm & 1000mm x 1200mm

- Test Speed: 12.5 ± 2.5 mm/min

- Speed Drive: 10mm/min to 50mm/min.

- Load Sensors: 4 Nos.

- Paint: Powder Coated

- Motor: Crompton/ Bharat Bijlee make Induction Motor (1hp/1.5hp/2hp, as per the machine capacity) & Drive

- Power: 220V AC, Single phase, 50 Hz

- Standard: ASTM D642, ASTM D4169

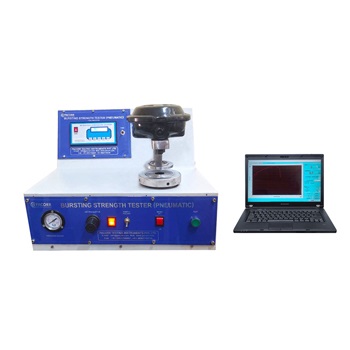

- Options: Computerized Model Available

Features:-

- Advance electronics for accurate test results

- 4 Load sensor based highly accurate machine

- Tare and Peak Hold Facility is provided

- Speed Drive 10mm/min to 40mm/min. provided

- Over travel protection

- Over load protection

- Very Strong, Heavy duty and rugged structure

- Digital LCD display with backlit

- Available in various platform sizes and Load Cell Capacity.

Why Box Compression Testing is Crucial

In supply chain operations, corrugated boxes are frequently stacked, handled roughly, and subjected to vibrations during transit. Without proper compression strength, boxes can collapse, leading to product damage and financial loss.

Box Compression Testing (BCT) simulates the stacking load a box might encounter and helps packaging engineers determine its maximum load-bearing capacity. This enables manufacturers to:

- Select the right box design and material

- Minimize packaging waste without compromising strength

- Ensure compliance with shipping regulations and international standards

Key Features of Pacorr’s Box Compression Tester

- Advanced Load Cell Technology: ±1% FSD precision

- Variable Platform Sizes: 600mm x 600mm to 1000mm x 1200mm

- Multiple Load Capacities: 500Kgf, 1000Kgf, 2000Kgf, and 3000Kgf

- Peak Hold & Tare Functions

- Overload & Overtravel Protection

- Digital or Computerized Display Options

- Heavy-duty construction for industrial use

Applications Across Industries

Pacorr’s Box Compression Tester is widely used in:

- Corrugated Packaging

- Warehousing and Logistics

- Consumer Goods Packaging

- Pulp and Paper

- Export and Freight

Ideal for bulk packaging, product transit, and retail storage where stacking resistance matters.

Standards Compliance

Complies with the following international standards:

- ASTM D642 – Compression Resistance of Shipping Containers

- ASTM D4169 – Performance Testing of Shipping Containers

- ISO 12048 – Compression and Stacking Tests for Transport Packages

These standards ensure credibility and acceptance in both domestic and international markets.

How the Test Works

- Sample Placement: Box is placed between compression plates

- Load Application: Constant-rate compression applied

- Data Logging: Peak force recorded by load cell

- Result Display: Digital or computerized readout displays the maximum force

This test replicates vertical pressure from stacking in real-world logistics.

Why Choose Pacorr for Box Compression Testing?

- Trusted by industry leaders across 25+ countries

- In-house manufacturing with expert R&D

- Optional computerized models with test data logging

- Technical support and calibration services

- Custom-built models for unique testing needs

Client Success Story

A packaging company faced high return rates due to collapsed cartons during transit. After installing Pacorr’s 2000Kgf Box Compression Tester, they standardized their packaging process and reduced in-transit damage by 40% in 3 months.

Get a Free Quote or Demo Today

Looking to ensure your packaging strength? Contact Pacorr for a tailored solution.

Call: +91-8882149230

Email: info@pacorr.com

FAQs – Box Compression Tester

Q1. What is the price of Box Compression Tester in India?

The price of Pacorr’s Box Compression Tester ranges between ₹1,20,000 and ₹5,50,000, depending on the load capacity, platform size, and whether you choose a digital or computerized model.

Q2. What is the maximum load capacity of the tester?

Pacorr offers models with load capacities of 500Kgf, 1000Kgf, 2000Kgf, and 3000Kgf to meet varying industrial requirements.

Q3. Is this tester suitable for export packaging validation?

Yes, it complies with ASTM D642, ASTM D4169, and ISO 12048 standards, making it ideal for domestic and international packaging evaluations.

Q4. Can the machine be connected to a computer system?

Absolutely. The computerized model includes software for real-time data logging, report generation, and graphical analysis.

Q5. What is the average delivery time for this equipment?

The standard delivery period is 2 to 3 weeks, depending on the customization and quantity ordered.

How to Use Box Compression Tester Video?

Write Your Review

Anand Mishra

Box Compression Tester is working fine and thanks for online installation.

Alok

Thanks for the heavy quality box compression tester.

Manish

Received best quality box compression testing machine.

Mithlesh Kumar

I recommend others to have business with Pacorr Testing Instruments.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.