Box compression tester computerised manufacturers and suppliers design and manufacture an instrument that is used in packaging industries for testing the quality and strength of the containers that are used for packaging in the industries such as corrugated boxes. The packaging containers are subjected to a variety of forces when they are stored or transported.

The packaging containers are subjected to a variety of forces when they are stored or transported. This can cause the boxes to be deflected and deformed which can compromise the integrity of the boxes and hence cause damage to the products inside the containers. This demands the manufacturers to ensure that the boxes have the ample strength to prevent deflection when they are subjected to such forces when they are being transported. The Strength of the boxes can be tested through many different test procedures and one of them is the compression test. The Pacorr Box compression tester computerized is one of the most accurate testing instruments that can be used for testing the compression strength of the packaging containers and corrugated boxes. The manufacturers need to ensure that the compression test is conducted accurately so that the most accurate analysis of the strength of the boxes could be ensured. With the box compression tester, the manufacturers can easily apply controlled forces on the boxes and containers and accurately measure the force that will cause deflection or deformation in the boxes.

Pacorr’s Box Compression Tester Computerized is the one instrument that essential needed by the packaging industries to test the strength of the packaging containers. The products that are packaged in containers such as corrugated boxes and cardboard boxes need to stay safe and sound during their transit and storage. The safety of the products is greatly dependent on the quality of the boxes that are sued for packaging of the products. The strength of the boxes needs to enough so that it could withstand the deforming forces that they are subjected to during transportation and storage. The most common force that is exerted on the packaging containers is the compression force that can easily deform the boxes if their strength is lower. This is why the manufacturers need to ensure the best strength of the containers.

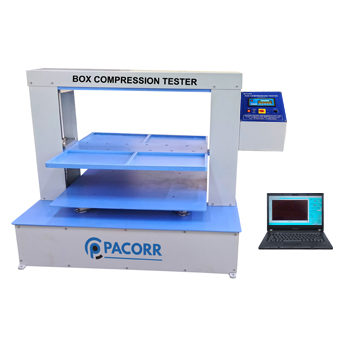

For this they can use the box compression tester computerised model. The instrument has a platform where the test specimen can be placed and then the moving plate of the instrument is moved to exert force on the specimen. The force is exerted until there is a deflection in the box and the force exerted on the box is noted. The load cell used in the instrument is very sensitive and efficient and can record even the smallest deflection in the specimen and the force applied for that deflection. The box compression tester computerized manufacturers and suppliers have equipped the instrument with a digital display which gives the reading for the force exerted on the box. In addition to the digital display, the computerised model is also given with a computer software and the computer which can be used for detailed analysis of the test data that is obtained through continuous testing of the specimen. With this instrument, the manufacturers can easily understand the behaviour of the corrugated boxes when they are subjected to high compressive loads.

It can customized by using different sizes of load cells for testing bigger size and capacity of boxes.

- Capacities: 500Kgf, 1000Kgf, 2000Kgf & 3000Kgf

- Display: LCD (Digital) with Backlit

- Accuracy: ± 1% of FSD.

- Least Count: 50gm to 500gm

- Test Platform Size : 600mm x 600mm, 800mm x 800mm, 1000mm x 1000mm & 1000mm x 1200mm

- Test Speed: 12.5 ± 2.5 mm/min

- Speed Drive: 10mm/min to 50mm/min.

- Load Sensors: 4 Nos.

- Paint: Powder Coated

- RS232 port to interface with PC/ Laptop

- Motor: Crompton/ Bharat Bijlee make Induction Motor (1hp/1.5hp/2hp, as per the machine capacity) & Drive

- Power: 220V AC, Single phase, 50 Hz

- Standard: ASTM D642, ASTM D4169, ISO 2234:2015, EN ISO 12048

- Advance electronics for accurate test results

- 4 Load sensor based highly accurate machine

- Tare and Peak Hold Facility is provided

- Speed Drive 10mm/min to 40mm/min. provided

- RS232 port to interface with PC/ Laptop

- Comptuterized report includes Graph Load vs Time, Max. Load, Operator ID, Date, Time etc.

- Over travel protection

- Over load protection

- Very Strong, Heavy duty and rugged structure

- Digital LCD display with backlit

- Computer / Laptop: Client Scope

- Available in various platform sizes and Load Cell Capacity.

Our Clients

A countless string of happy and satisfied customers vouch for our

excellence and complete quality control support.