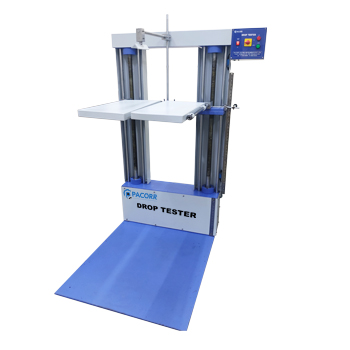

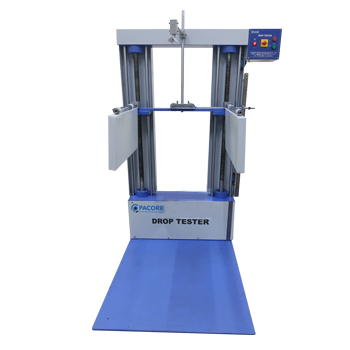

Pacorr’s Drop Tester is a reliable instrument used to evaluate the strength and impact resistance of packaging products. Designed to simulate free-fall drops, it helps identify packaging flaws that could result in product damage during transit, handling, or stacking.

Whether you are shipping electronics, pharmaceuticals, consumer goods, or industrial components, ensuring packaging performance under drop conditions is critical. Pacorr’s Drop Tester provides accurate drop simulation to help manufacturers achieve product safety, reduce returns, and meet international packaging standards.

- Shipping Area: All over the world

- Model: PCDT-1

Key Features

- Adjustable drop height to simulate various fall scenarios

- Twin flap or single flap drop mechanism

- High-precision guide rail for accurate vertical drop

- Rigid steel structure for stable and repeatable results

- Suitable for multiple box sizes and materials

- Complies with ISTA and ASTM testing standards

Technical Specifications

- Drop Height Range: 300 mm to 1800 mm

- Max Load Capacity: Up to 60 kg

- Drop Mechanism: Twin flap / single flap

- Drop Angle: Flat, edge, or corner

- Platform Size: 800 x 800 mm (customizable)

- Standards Compliance: ISTA 1A, ASTM D5276, ISO 2248, JIS Z0202

Applications

- Corrugated box testing

- Electronic item packaging durability

- Consumer goods packaging analysis

- Home appliance transit protection

- Export packaging validation

- Pharmaceutical and cosmetic products safety

Why Drop Testing is Critical

- Verifies packaging resistance to impact and vibration

- Ensures products remain intact during logistics handling

- Helps design cost-efficient yet protective packaging

- Prevents loss due to breakage and returns

- Meets domestic and international shipping compliance

Use Case – Solving Damage Issues in Export Packaging

- Client: Exporter of ceramic home décor products

- Problem: Products were getting chipped or broken during overseas shipments

- Solution: Pacorr installed a Drop Tester for pre-shipment packaging validation

- Result: Packaging was optimized, product breakage reduced by 90 percent, and client satisfaction improved

How It Works

- The test sample (usually a packed product or box) is placed on the drop arms

- Drop height is set as per required simulation scenario

- Drop arms are released simultaneously to allow the box to fall freely

- The box impacts the ground, and product integrity is visually inspected

- Multiple drops can be conducted on flat surface, edge, or corner

Drop Testing Types Supported

- Flat Drop – Tests product endurance when dropped flat

- Edge Drop – Simulates impact on box edges

- Corner Drop – Simulates most severe drop on package corner

- Rotational Drop – Available in specialized models for dynamic testing

Compliant with International Standards

Pacorr’s Drop Tester is manufactured in accordance with these globally recognized packaging test methods:

- ASTM D5276 – Standard Test Method for Drop Test of Loaded Containers

- ISTA 1A and 2A – Procedure for testing packaging performance in transit

- ISO 2248 – Packaging – Complete filled transport packages – Vertical impact test

- JIS Z0202 – Japanese industrial standard for drop tests of transport packages

Benefits of Using Pacorr’s Drop Tester

- Prevents in-transit damages and related losses

- Reduces packaging costs through better optimization

- Enhances packaging design through data-driven insights

- Meets compliance for domestic and international shipping

- Ensures consistent packaging quality across production batches

Who Needs Drop Testing

- Export packaging companies

- Corrugated box manufacturers

- Food and beverage brands

- Electronics and gadgets brands

- Pharma packaging companies

- E-commerce warehouses and logistics providers

Model Options Available

- Manual Drop Tester – Basic version with hand-operated drop mechanism

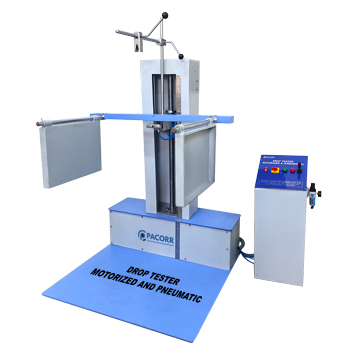

- Motorized Drop Tester – For faster and repeated drop testing

- Custom Drop Height Model – For special products like tall electronics

- Pneumatic Drop Tester – For heavy-duty testing requirements

Frequently Asked Questions (FAQ)

Q1. What is the use of a Drop Tester

It is used to simulate free-fall conditions and assess the durability of packaging and products against drop impact.

Q2. What packaging materials can be tested

Corrugated boxes cartons plastic containers and composite packaging materials can all be tested.

Q3. What is the standard height used in drop tests

Common testing ranges are 300 mm to 1800 mm but can be customized as per test standards.

Q4. What is the price range of Drop Tester?

Pacorr offers Drop Tester models from 85000 to 220000 INR depending on configuration.

Q5. Can we conduct corner and edge drops with this machine

Yes Pacorr’s Drop Tester supports flat edge and corner drops as per international standards.

Want to ensure your products reach customers in perfect condition?

Get the Pacorr Drop Tester and secure your packaging quality today.

Call us at +91-8882149230 or email [email protected] for a demo or quote.

Write Your Review

Vishnu

You are using very high quality material for making drop tester and other testing instruments.

Deepak Kumar

My company is satisfied to using Pacorr Drop Tester.

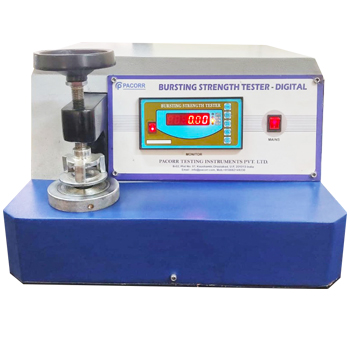

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.