Paint Bucket compression test is to measure the force required to secure the lid provided on the bucket so that bucket lids will not collapse when stacked one above the other. The test helps to understand the performance of the bucket lids, its sealing, and shipping characteristics.

Paint buckets are widely used for storing a large quantity of paints, coatings and laminates. These buckets are widely known as pails in the market. The pain buckets are air tight containers that help to avoid spillage and contamination of the products that are packed inside. Paint buckets are not only used to fill paints but can also be reused for multiple purposes at home by the end users. Paint buckets are of two types: metal paint buckets and plastic paint buckets. These buckets are available in different colors and sizes to fulfill different requirements of the customers. The market of paint buckets is very large and hence very competitive too.

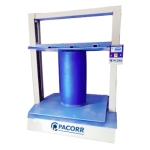

With the wide usage of paint buckets, it becomes important for the manufacturers to produce high-quality buckets using advanced techniques, testing procedures and cost-effective manufacturing processes. Major issues that are held with paint buckets is the compression. To ensure that high-quality buckets are manufactured, manufacturers perform a Paint Bucket Compression Test.

Purpose of Compression Test

The purpose of the compression test is to measure the force required to secure the lid provided on the bucket so that bucket lids will not collapse when stacked one above the other. The test helps to understand the performance of the bucket lids, its sealing, and shipping characteristics.

- Type: Compression

- Capacity: 2000Kgf

- Display: Digital, LCD with Backlit

- Accuracy: ± 2% full scale (with master load).

- Least Count: 200gm

- Power: 220V, Single phase, 50 Hz

- Test Platform Size : 800mm x 800mm x 800mm

- Test Speed Range: 10 mm/min to 50 mm/min.

- Speed Drive: 10mm/min to 50mm/min.

- Standard: ASTM D642, ASTM D4169

- Options: Computerized Model Available

- Microprocessor based display for accurate test results

- Highly accurate test results under uniform compression Force

- TARE and Peak Hold Facility Available

- Over travel protection

- Strong base plate with rugged structure

- LCD display with backlit

- Available in various platform sizes and Load Cell Capacity.

Our Clients

A countless string of happy and satisfied customers vouch for our

excellence and complete quality control support.