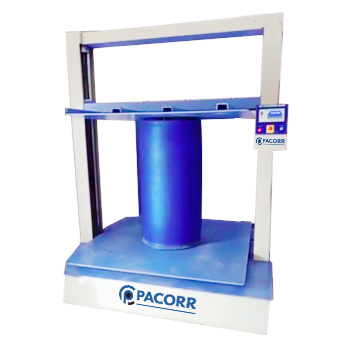

Drum Compression Tester is majorly used to test the quality of plastic drums. The testing instrument helps to calculate the amount of compressive force a plastic drum can tolerate when the force is applied in a vertical direction. The force is applied until the sample deforms or collapses to test the maximum compression strength. The testing instrument is designed keeping in mind the national and international standards (ASTM D642, ASTM D4169). It comes with a digital display panel, and user-friendly control panel that helps to conduct the test easily and provides accurate test results.

Plastic drums are one of the common means of storage. These barrels are used in wide number of industries. These drums are beneficial to use especially when it comes to long-term storage of goods in large quantities. Plastic drums or plastic barrels are commonly used in supermarkets, warehouses and storage areas all across the world to store liquids in large quantities. Be it beverages in food industries, chemicals in pharmaceutical industries, paints and coatings in paint industries, oil in oil refinery units, we need plastic barrels to store the liquids.

To fulfill the liquid storage needs in different industries, plastic drum and barrel manufacturers need to ensure that the drums they are manufacturing in their premises are of superior quality. Once the barrels and drums are manufactured and come into usage, they have to tolerate a lot of compression strength at the time of storage, warehousing and transportation, especially when stacked one above the other.

To ensure the compression strength of plastic drums, the manufacturers need to make use of the testing machine - Drum Compression Tester.

DCT or Drum compression tester is a standardized, and accurately designed testing equipment that can create the warehousing / transportation stacking scenario inside the laboratory. The testing equipment is used to provide predefined compressive load on the drum and calculate its maximum compressive strength before it gets ruptured.

The testing machine comes with heavy-duty and sturdy, moving compressive plates which has a load cell capacity of 3000 KGF / 3 tonnes. The load cell helps to exert optimum amount of pressure on the sample uniformly.

The testing apparatus has a rigid platform that helps to place a wide variety of drum sizes on the machine. It comes with a digital display that helps to take quick and accurate reading. The user-friendly control panel with soft-touch buttons helps to set the required parameters very easily.

Moreover, the machine comes with a few state of the art features like an auto-cut off facility that automatically stops the working process when it senses the deflection in the sample, and a peak hold feature that records and saves up to ten results for future analysis. The machine is duly powder coated that enhances its shelf life.

- Type: Compression

- Capacity: 3000Kgf

- Display: LED (Digital)

- Accuracy: ± 2% full scale (with master load).

- Least Count: 500gm

- Power: 220V, Single phase, 50 Hz

- Test Platform Size : 800mm x 800mm x 1100mm

- Test Speed: 12.5 ± 2.5 mm/min

- Speed Drive: 10mm/min to 50mm/min. (Optional)

- Standard: ASTM D642, ASTM D4169

- Options: Computerized Model Available

Our Clients

A countless string of happy and satisfied customers vouch for our

excellence and complete quality control support.