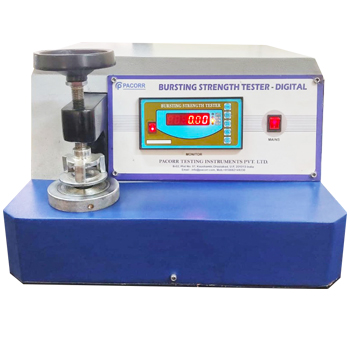

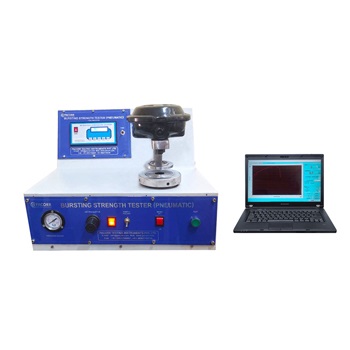

Pacorr’s Bursting Strength Tester – Pneumatic is a high-precision testing instrument designed to measure the burst strength of materials like corrugated cardboard, paper, textile fabrics, and leather with exceptional accuracy. It provides a quick assessment of how much pressure a material can withstand before rupturing, which is crucial for industries that demand durable packaging and products. Engineered with a pneumatic clamping system and advanced digital controls, this tester ensures secure, slip-free sample holding and delivers consistent, reliable results for quality assurance in packaging, textiles, and paper manufacturing. The professional, robust design and compliance with international standards make Pacorr’s pneumatic bursting strength tester stand out as a trusted solution for material strength testing in demanding industrial environments.

- Shipping Area: All over the world

- Model: PCBSTD-70P

Spcification:-

- Capacity: 0 to 70 Kg/cm²

- Least Count: 0.1 Kg/cm²

- Display Type: Digital

- Clamping System: Pneumatic

- Required Air Pressure: 2 to 5 Bar

- Upper Clamp Opening Diameter: 35.5 mm

- Lower Clamp Opening Diameter: 38.1 mm

- Fluid Displacement Rate: 95 cc/min

- Test Medium: Glycerin

- Motor: ¼ HP, Single Phase

- Peak Hold Function: Available

- Safety Switch: Integrated

- Accuracy: ±1% (within 10% to 90% of full range) as per IS:1828

- Compliant Standards: ASTM D3786, ASTM D774

Overview & Working Principle

In packaging and materials industries, bursting strength is an essential metric that indicates the maximum force a material (like a paper sheet, cardboard, or fabric) can endure before it bursts or ruptures. Pacorr’s Pneumatic Bursting Strength Tester is built to accurately simulate these conditions by applying uniform pressure until the sample fails. The test specimen is clamped securely between two circular plates, and pressure is gradually applied via a hydraulic fluid (lab-grade glycerin) beneath a flexible rubber diaphragm. As the diaphragm expands, it exerts multi-directional force on the specimen until it bursts, at which point the machine records the peak pressure (burst strength) on its digital display.

Pacorr’s tester employs a pneumatic clamping mechanism to hold the sample firmly in place during testing. Instead of manual tightening, compressed air applies the clamping force, which guarantees a tight, slip-free grip without operator variation. This pneumatic operation not only makes testing easier (with one-touch clamping) but also improves accuracy by eliminating slippage and ensuring the pressure is applied uniformly across the sample. A microprocessor-controlled system monitors the pressure increase and identifies the exact point of burst, capturing the peak value automatically. A backlit digital screen displays the burst strength value, and the data can be transferred to a computer for detailed analysis and record-keeping.

Key Features

- Pneumatic Clamping & One-Touch Operation: Fast and consistent specimen mounting without slippage. Improves result repeatability and test efficiency.

- Digital Display with Graphical Readouts: Real-time pressure values with peak hold function. Microprocessor-based controls ensure ±1% accuracy.

- High Build Quality & Safety: Durable construction, grooved clamps, pure rubber diaphragm, and emergency safety switch for operator protection.

- Standards Compliance & Accuracy: Calibrated to ASTM D774, ASTM D3786, ISO equivalents for global acceptance in QC and R&D labs.

Applications in Packaging, Textiles, and Paper

Corrugated Boxes & Paper Packaging:

Ideal for testing paperboards, carton stock, and shipping containers to ensure they withstand stacking, transit, and handling pressures.

Printing & Paper Manufacturing:

Used for kraft paper, newsprint, and multilayered sheets. Calculates bursting factor and index to grade paper quality.

Textile and Fabric Testing:

Evaluates bursting strength of woven/non-woven fabrics and technical textiles such as airbags or geotextiles under ASTM D3786.

Leather and Synthetic Leather:

Determines durability of upholstery, automotive leather, and rexine, ensuring resistance to rupture under load.

Additional Materials:

Also applicable to aluminum foils, plastic films, laminated sheets, and other flexible materials where burst resistance is critical.

Benefits & Advantages

- Reliable Quality Control: Ensures compliance with strength standards and minimizes product failures during use or transport.

- Enhanced Accuracy and Consistency: Pneumatic clamping removes operator error; tests yield highly repeatable results.

- Efficiency and Ease of Use: Speeds up testing cycles with one-button operation, peak hold, and auto zero functions.

- Data Analysis and Reporting: PC connectivity supports report generation and statistical analysis for audits and quality certifications.

- Durability & Low Maintenance: Built to last with industrial-grade materials, easy calibration, and low operating costs.

Why Pacorr’s Pneumatic Bursting Strength Tester Stands Out

Pacorr’s pneumatic bursting strength tester integrates ease of use, accuracy, and data connectivity into one unit, delivering unmatched reliability across multiple industries. With features like pneumatic clamping, real-time digital feedback, and robust construction, it enables manufacturers to maintain product quality, reduce returns, and meet international standards efficiently. It’s the ideal solution for labs and production floors where material strength plays a key role in product success.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.