Summary: An edge crush tester is a device used to measure the edgewise compression strength of corrugated cardboard. This measurement, known as the Edge Crush Test (ECT), is essential for determining the stacking strength of a cardboard box, which is crucial for packaging design and logistics. The tester applies a compressive force to a small section of the material until it collapses, and the maximum force sustained is recorded. The results from this test help manufacturers ensure that their cardboard packaging can withstand the pressures of stacking during shipping and storage, optimizing both product safety and cost efficiency. Edge Crush Tester brings hi-end features and technology to test packaging box raw material like corrugated or non-corrugated cardboard sheets. The edge crush tester evaluates how resistant a cardboard edge is against a vertical crushing load. It can analyze the strength and sturdiness of cardboard sheets by performing Edge Crush Test (ECT). With the precise value of ECT, the manufacturer can categorize the material for packaging box use and have a reality check on how the cardboard will perform.

- Shipping Area: All over the world

- Model: PCECT

Specification:

- Capacity: 100Kgf

- LCD Display with Backlit

- Measuring Unit: kgf

- Least count: 0.02 kgf

- Accuracy: ± 1%

- Test speed: 12.5 mm/min.

- Speed Range: 10mm/min to 50mm/min.

- Platen Size: 150mm Diameter.(Upper & Lower)

- Fixtures for testing Ring Crush, Flat Crush & Edge Crush shall be provided.

- Material of Construction: M.S Powder coated and Hard Chromed

- Mottor: 0.5hp, 3 phase (Crompton/ Bharat Bijlee make) with Gearbox

- Speed Drive: Crompton/ Delta make

- Power: 220 VAC, Single Phase, 50Hz

- Related Standards: IS 7063-2

Features:

- Microprocessor-based highly precise display.

- Precision Load Sensor

- Peak-Hold and Tare facility available

- Fixtures for Ring Crush, Edge Crush and Flat Crush Test shall be provided.

- Uniform compressive force to get accurate results.

- Rugged Structure

- Strong gripping clamps for tight specimen hold

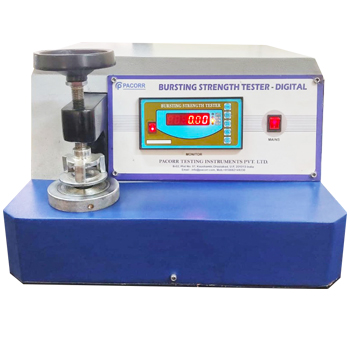

Overview of Edge Crush Tester

With Pacorr’s Edge Crush Tester, manufacturers can accurately evaluate the strength and durability of their corrugated packaging, ensuring it meets international shipping and stacking standards.

Why Choose Pacorr’s Edge Crush Tester?

- Precise Edge Strength Measurement with repeatable and reliable results

- High-Quality Load Cell Sensor for accurate force detection

- User-Friendly Operation for quick and efficient testing

- Strong Body Frame for vibration-free performance

- Compliance with International Standards like ASTM D7030, TAPPI T811, ISO 3037

Key Features of Pacorr Edge Crush Tester

- High-Resolution Digital Display showing real-time force values

- Automatic and Manual Testing Modes available

- Advanced Load Cell Technology for precise force measurement

- Rigid, Powder-Coated Steel Body for long-lasting use

- Wide Testing Range suitable for single-wall, double-wall, and triple-wall boards

- Optional Computer Connectivity for data logging and reporting

- User-Safe Design with overload protection features

Applications of Pacorr Edge Crush Tester

| Industry | Application |

| Corrugated Box Manufacturers | Ensure box stacking strength |

| Packaging Companies | Validate material quality |

| E-commerce & Logistics | Ensure product safety during transit |

| FMCG Sector | Verify packaging durability |

| Electronics & Appliances | Protect heavy products with strong boxes |

How Pacorr Edge Crush Tester Works

- Cut the corrugated board into standard test specimen sizes.

- Place the specimen vertically between two compression plates.

- Initiate the compression test through the control panel.

- The machine applies vertical load until the board edge collapses.

- Record the maximum load value, known as the Edge Crush Test (ECT) value.

Technical Specifications of Edge Crush Tester/ RCT/FCT

- Load Range: Up to 1000 N (customizable)

- Accuracy: ±1% of the reading

- Display: Digital / Touchscreen (optional)

- Compression Speed: Adjustable

- Test Modes: ECT, RCT (Ring Crush Test), FCT (Flat Crush Test)

- Sample Size: As per ASTM / TAPPI / ISO standards

- Standards Met: ASTM D7030, TAPPI T811, ISO 3037

Benefits of Using Pacorr Edge Crush Tester

- Improve stacking strength of corrugated boxes

- Optimize material usage without compromising strength

- Reduce transit damages and customer complaints

- Meet global packaging and export standards

- Strengthen brand reputation with reliable packaging solutions

| Aspect | Details |

| Instrument Type | Edge Crush Tester, designed for assessing packaging strength. |

| Primary Use | Testing the edge crush resistance of corrugated boxes and similar packaging materials. |

| Standards Conformance | TAPPI, ISO, ASTM, BS EN ISO standards for reliability and industry acceptance. |

| Digital Features | Advanced digital models available for precise, efficient testing. |

| Significance | Ensures packaging can withstand transportation and storage rigors, reducing damage risks. |

| Material Suitability | Ideal for corrugated cardboard, paperboard, and various packaging materials. |

| Maintenance Requirements | Periodic maintenance advised for optimal performance and reliability. |

FAQs about Pacorr Edge Crush Tester

Q1. How does a Edge Crush Tester work?

A. An Edge Crush Tester measures the edgewise compressive strength of corrugated cardboard by applying gradual pressure to a sample placed vertically between two plates. As force increases, the tester records the pressure at which the board buckles or fails. This test helps manufacturers evaluate how well packaging can withstand stacking and shipping stress, ensuring durability in transit.

Q2. Can the Edge Crush Tester test materials other than corrugated cardboard?

A. Yes, while the primary use of an Edge Crush Tester is to evaluate the edge crush resistance of corrugated cardboard, it is also capable of testing a variety of other packaging materials. This includes paperboard and other forms of packaging materials, offering a versatile tool for quality control in packaging.

Q3. What standards do Edge Crush Testers conform to?

A. Edge Crush Testers are designed to meet a variety of international standards to ensure their testing results are reliable and consistent. Common standards include TAPPI T 811 / T 812 for corrugated fiberboard, ISO 3037 for the edgewise compressive strength of corrugated fiberboard, ASTM D4727 for corrugated and solid fiberboard sheet structures, and BS EN ISO 3037. Compliance with these standards ensures the tester is suitable for global use.

Q4. Are there digital models of Edge Crush Testers available?

A. Yes, Pacorr offers digital models of the Edge Crush Tester, which come with advanced features such as microprocessor-based displays, precision load sensors, and computer connectivity for better analysis. These digital models provide more precise and efficient testing, making them suitable for modern quality control labs.

Q5. How important is periodic maintenance for an Edge Crush Tester?

A. Periodic maintenance is essential for ensuring the Edge Crush Tester remains accurate and reliable over time. Regular checks and calibrations can prevent potential inaccuracies in test results, which is crucial for maintaining quality control in packaging. Manufacturers often provide maintenance guidelines and services to keep the equipment in optimal condition.

Q6. What is the price of an Edge Crush Tester (ECT/RCT/FCT)?

A. The price of an Edge Crush Tester capable of performing ECT, RCT, and FCT typically ranges between ₹85,000 and ₹2,00,000 in India, depending on the brand, model, and additional features. For an exact quote, it’s best to contact the supplier directly.

Conclusion

If you want to ensure your packaging is strong, reliable, and meets international standards, trust Pacorr’s Edge Crush Tester. It’s the perfect investment for better quality control, improved packaging designs, and reduced shipment damages.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.