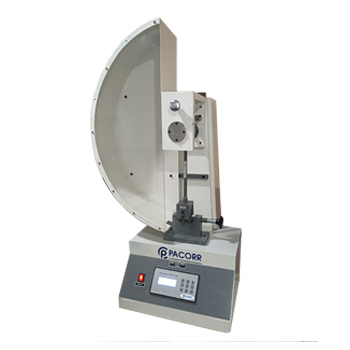

Melt Flow Index Tester is a precision-engineered instrument designed to determine the flow properties of thermoplastic polymers. By accurately measuring the melt flow rate (MFR) or melt volume rate (MVR), this equipment helps manufacturers assess material behavior under standardized temperature and pressure conditions. Ideal for plastic processors, compounders, and quality control labs, Pacorr’s MFI Tester ensures compliance with ASTM D1238 and ISO 1133 standards.

- Shipping Area: All over the world

- Model: PCMFIT-1

Specification:-

- Temperature Controller: Microprocessor based Digital Temperature Controller

- Temperature Range: Upto 400 deg. C

- Resolution: 0.1 deg. C

- Accuracy: +/- 0.1 % F.S.D.

- Timer: Microprocessor based Digital Timer with range up to 999.9 Seconds and having Preset facility and buzzer output.

- Weights: 2.16 Kg & 5 Kg hard chrome plated weights.

- Accessories: Orifice, Piston, Barrel Cleaner, Orifice cleaner etc.

- Sample Cutting: Auto-Cut

- Paint: Powder Coating.

- Power: 230V AC, 50 Hz

- Amperes: 4 Amps.

- Table Top Model

Features:-

- Sample Cutting, Auto cutting

- Automated Sample Cutting facility

- Comes with digital temperature controller and indicator

- Duly powder coated outer body for long life and corrosion resistance

- Comes with different load weights

- Greater accuracy with digital preset timer

Overview of Melt Flow Index Tester

Pacorr’s Melt Flow Index Tester is a precision-engineered instrument designed to determine the flow properties of thermoplastic polymers. By accurately measuring the melt flow rate (MFR) or melt volume rate (MVR), this equipment helps manufacturers assess material behavior under standardized temperature and pressure conditions. Ideal for plastic processors, compounders, and quality control labs, Pacorr’s MFI Tester ensures compliance with ASTM D1238 and ISO 1133 standards.

Understanding the Melt Flow Index (MFI)

The Melt Flow Index (MFI) is a key parameter that defines the ease of flow of a molten thermoplastic material. It is measured in grams per 10 minutes and is critical in assessing the processing performance of materials in injection molding, extrusion, and blow molding operations. A higher MFI indicates lower viscosity, while a lower MFI means higher resistance to flow.

Pacorr's Melt Flow Index Tester offers advanced digital and computerized models that provide accurate, reproducible results with minimal operator intervention. This helps quality analysts determine batch-to-batch consistency, material degradation, and suitability for specific applications.

Why Melt Flow Testing is Essential?

- Quality Control: Helps identify variations in material lots, ensuring consistent output quality.

- Process Optimization: Allows selection of the correct processing temperature and pressure for extrusion/molding.

- Material Comparison: Enables comparison of different grades of plastic for desired mechanical performance.

- Regulatory Compliance: Ensures materials meet standards such as ASTM D1238, ISO 1133, and customer specifications.

Types of Models Available at Pacorr

- Manual MFI Tester: Suitable for basic testing applications with standard die and piston configuration.

- Digital MFI Tester: Equipped with microprocessor-based display, timer, and automatic cutting mechanism.

- Computerized MFI Tester: Comes with software integration, real-time graphing, and data recording. Includes weighing scale and PC connectivity for advanced analysis.

Key Features

- Precise temperature control up to 400°C with PID controller

- High-quality barrel and piston for consistent extrusion

- Digital display for real-time temperature and timer

- Replaceable dies and weights for testing various materials

- Advanced software (in computerized models) for test data management

- Conforms to ASTM D1238 and ISO 1133 standards

- Optional built-in weighing scale in computerized model

- Auto sample cutter for uniform pellet separation

Benefits of Using Pacorr Melt Flow Index Tester

- Highly Accurate Results: Ensures repeatable and reliable MFR/MVR values across all test cycles.

- Time-Saving: Quick heat-up time and auto-cutting enhance lab productivity.

- User-Friendly Interface: Simplified controls with clear digital readings make operation easy even for beginners.

- Robust Construction: Built with industrial-grade materials for long-term durability.

- Data Management: With the computerized model, users can generate reports, compare results, and maintain digital logs.

- Cost-Efficiency: Prevents raw material wastage by detecting improper resin grades before processing.

- Multi-Industry Application: Suitable for use in automotive, packaging, consumer goods, cable manufacturing, and masterbatch production.

Applications of MFI Tester

- Plastic Resin Manufacturers

- Quality Control Laboratories

- Injection Molding and Extrusion Plants

- Research and Development Centers

- Polymer Compounders and Recyclers

Why Choose Pacorr for MFI Testing?

- Industry-leading accuracy with certified calibration traceability

- Dedicated technical support and after-sales service

- Customization available as per client testing requirements

- Export-ready models with CE marking and global compliance

- Trusted by top brands in plastic and packaging industry

FAQs – Melt Flow Index Tester

Q1. What is the price of Melt Flow Index Tester?

A. Pacorr offers MFI Testers in a price range of ₹50,000 to ₹2,00,000 depending on the model (manual, digital, or computerized), add-ons, and customization.

Q2. What standards does this machine comply with?

A. The tester strictly complies with ASTM D1238, ISO 1133, and other international testing norms for thermoplastics.

Q3. What materials can be tested with this machine?

A. It is suitable for materials like PP, PE, ABS, PVC, PS, PET, and various engineering plastics.

Q4. Does Pacorr provide a calibration certificate?

A. Yes, every machine is delivered with standard calibration certificate traceable to NABL-accredited labs.

Q5. Can it test recycled plastic granules?

A. Absolutely. It helps assess the flow behavior of recycled granules and detect degradation or contamination.

Conclusion

Pacorr’s Melt Flow Index Tester is a must-have quality testing solution for industries dealing with thermoplastics. From resin manufacturers to plastic product suppliers, ensuring the correct melt flow rate can significantly improve product performance, consistency, and compliance. With its precise engineering, advanced features, and robust construction, Pacorr stands as a reliable partner in quality control excellence.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.