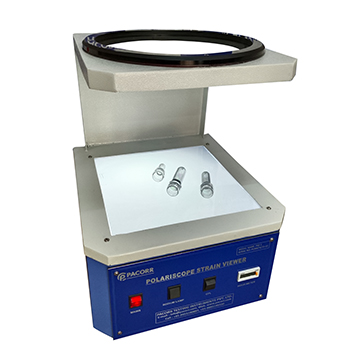

Pacorr’s Polariscope Strain Viewer is a high-precision optical inspection tool designed to evaluate stress distribution and transparency in PET preforms, glass products, and other transparent materials. It plays a critical role in quality control by detecting internal strain patterns that may compromise product integrity.

- Shipping Area: All over the world

- Model: PSP-1

The instrument works on the principle that variations in the material's refractive index, caused by uneven strain, reduce transparency a phenomenon known as photoelasticity. This is particularly significant for manufacturers of PET and glass items, where undetected internal stress can lead to breakage or performance failure.

Pacorr offers two advanced models: the Polariscope Digital Model and the Polariscope Computerized, each tailored to different inspection needs. The Digital model features a digital display for clearer visualization and user-friendly operation, making it ideal for modern QC labs. Built with corrosion-resistant materials and a refined zinc and chrome finish, these instruments are designed for long-term, reliable use. The grey and blue exterior adds a sleek, professional look to the unit.

Every Polariscope unit is supplied with a calibration certificate traceable to NABL-accredited labs, along with a comprehensive instruction manual. Available in multiple sizes and specifications, Pacorr’s Polariscope is the go-to solution for manufacturers seeking accuracy, durability, and dependable quality assurance.

Key Features

- Dual light source – monochromatic and polarized

- Compact and table-top design

- Comes with standard strain interpretation chart

- High transmission LED illumination

- Suitable for PET preforms and blow-molded bottles

- Optional digital model with camera and software analysis

Technical Specifications

- Viewing Area: 260 x 260 mm

- Light Source: LED / CFL

- Observation Modes: White light and polarized light

- Frame Material: Powder-coated steel or acrylic (as per model)

- Compatible Sample Types: Preforms, containers, bottle necks

- Operation: Manual or digital

Applications

- PET bottle manufacturing

- Preform quality testing

- Cosmetic packaging inspection

- Pharmaceutical bottle QC

- Transparent molded parts analysis

- Laboratory R&D for polymers and plastics

Frequently Asked Questions (FAQ)

Q1. What is the use of a Polariscope Strain Viewer

It helps identify internal stress and birefringence in PET preforms, bottles, and other transparent materials to ensure product quality and structural integrity.

Q2. Can it detect defects in plastic caps or vials

Yes, it’s effective for inspecting transparent caps, vials, ampoules, and molded plastic components for stress-related flaws.

Q3. Is the Polariscope available in a digital model

Yes, Pacorr offers a digital variant equipped with a camera and software for real-time viewing, recording, and detailed stress analysis.

Q4. What is the price range of Polariscope Strain Viewer in India

The price typically ranges from ₹28,000 to ₹95,000, depending on model type, viewing area, and additional features.

Q5. How is it different from visual inspection

Unlike the naked eye, a Polariscope uses polarized light to expose internal stresses, offering far greater precision and reliability.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.