Measure Ash Content of Food Material Using Muffle Furnace

In the present industrial scenario, the most important factor that is affecting the sales of the products is the quality of the products. Customers are becoming more and more quality conscious when it comes to buying products. When people are paying high prices for the products they buy, then it is expected by them that they will receive the best quality of products from the manufacturers. This also makes the manufacturers also very conscious about the quality of products they produce as it is only possible with great quality to compete with other brands in the market. This is why the manufacturers take every possible step to ensure that the quality of their products is of top notch level.

In order to ensure best level of quality of any product, first of all, it is essential to know everything about the raw materials being used for manufacturing a product. The composition of the raw materials helps the manufacturers in deciding the best manufacturing procedure that can incorporate high quality in the products. One of the easiest ways to study the composition of any material is to burn them into ashes and then study the ashes for the minerals and other components present in the materials. This method is used in food industries extensively to determine the amount of minerals and micronutrients present in the food products. For this, it is important that the test sample is turned into ashes without the interference of any external factor. The muffle furnace is one of the most commonly used device for carrying out the combustion of the test samples in isolation and turn them in to ashes completely without any interference of the external factors.

In order to ensure best level of quality of any product, first of all, it is essential to know everything about the raw materials being used for manufacturing a product. The composition of the raw materials helps the manufacturers in deciding the best manufacturing procedure that can incorporate high quality in the products. One of the easiest ways to study the composition of any material is to burn them into ashes and then study the ashes for the minerals and other components present in the materials. This method is used in food industries extensively to determine the amount of minerals and micronutrients present in the food products. For this, it is important that the test sample is turned into ashes without the interference of any external factor. The muffle furnace is one of the most commonly used device for carrying out the combustion of the test samples in isolation and turn them in to ashes completely without any interference of the external factors.

The muffle furnace is an instrument that is provided with a closed chamber where the test sample can be placed. The device comes with a heating arrangement that can be used for combustion of the sample.

Any organic content leaves ash when they are burnt down. These ashes are inorganic content that is exists in any material. Any material heated to its burning point in the presence of oxidizing agents, ash is left. To evaluate the quality of a material, it is crucial to assess the existence of inorganic components. The various processes that measure the ash content in the food products are:

- Dry Ashing

- Wet Ashing

- Low-temperature ashing

The test procedure is chosen on the basis of their application of the material, requirements of the sample, and specifications of the sample. The test method analyses the minerals that exist, as they can be distinguished easily.

In the food industry, to ensure the quality of food, various tests are conducted. In recent years, ash testing is going to speed up the trend as it shows quality. Minerals that are present in the material can be assessed with this test. As per standard, the existence of 5% ash is acceptable, more than this helps in identifying the age of the food.

To perform the ash test, preparing the sample is an important part. The food sample should be in powdered form. Any moisture content that is present is dried first and leads to spraying at the time of heating. Fatty food samples leave moisture when dried that resists spattering.

Another problem that arises is contamination of the sample due to surroundings or the container utilised to hold the sample. The weight of the sample must be between 1 to 10 grams.

Various methods to perform the test with Muffle Furnace are:

- Wet Ashing- This method determines ash content in a food sample. It is a faster method than other techniques. The time span ranges from 10 minutes to a few hours. In this process, the temperature range is set at 350°C.

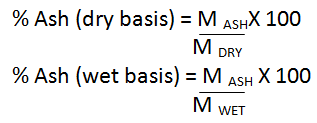

The difference in weight prior to and after the test is the percentage of ash content.

Where,

MASH = Mass of the ash sample,

MDRY= Refers to the mass of the dried sample,

MWET= Refers to the mass of the wet sample.

- Dry Ashing- In this method, Muffle furnace burns down the sample. The temperature of the chamber is set to approximately 600°C. At this temperature, the water evaporates from the sample and the rest of the material are burnt down. The minerals are transformed into oxides, sulphates and phosphates. Due to the presence of volatile materials in the test sample, the test outcome might become inaccurate.

The muffle furnace offered by Pacorr is made from high grade mild steel from outside and stainless steel from inside. Proper insulation is provided to avoid any type of heat escaping from the device. There is a digital controller given with the device which is very helpful in monitoring of the time as well as the temperature in the chamber. The temperature is controlled with two Kanthal wires heating elements and an advanced PID controller. With the help of this instrument, the manufacturers in the food industry can easily assess the ash content of their products and ensure that they are able to deliver high quality products to the customers.