Notch Cutter-Motorized manufacturers and suppliers make sure that they are able to provide the best precision testing instruments for the plastic industries so that the quality of the products could be controlled in an effective manner. IN the plastic industries, different products are manufactured with different physical strength and composition according to the usage purpose and working environment. For products that have to bear heavy forces and impacts, it is important that the products have enough physical strength and endurance to ensure that the products will be able to survive the impacts and forces without any fracture, breakage or failure.

| Aspect | Details |

|---|---|

| Usage | Preparation of test specimens for Charpy and Izod impact tests |

| Importance | Essential for accurate testing and quality assurance in the plastic industry |

| Features | Motorized operation, precision depth micrometer, and cutting angle of 45° |

| Applications | Plastic industries, particularly for products subjected to heavy forces |

| Compliance | Helps in adhering to testing standards for accurate results |

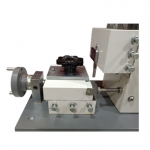

The Notch Cutter Motorized is a critical instrument designed for the meticulous preparation of specimens for the Charpy and Izod impact tests. These tests are fundamental for assessing the strength and durability of plastic materials under high-impact forces. Pacorr stands out as a leading supplier of such precision testing instruments, catering specifically to the needs of the plastic industry.

The Essence of Notch Cutter Motorized

The device is engineered for motorized operation, ensuring uniform and precise notches crucial for accurate impact testing. It incorporates a Japan-made micrometer, promising unparalleled measurement accuracy. Its operational range spans from 0 to 25mm, with a least count of 0.01mm, which is vital for preparing specimens according to prescribed testing standards.

Design and Features

Notably, the cutter is designed with a 45-degree cutting angle and is coated with a durable powder coating, highlighting its robustness and longevity. This tool is indispensable for industries that demand the highest levels of safety and reliability in plastic products.

Why Notch Cutter Motorized is Indispensable

In the highly competitive plastic industry, ensuring product quality is not just about compliance but also about securing a market edge. Products manufactured with varying physical strengths must undergo rigorous testing to guarantee performance under extreme conditions. The Notch Cutter Motorized facilitates this by preparing specimens for impact testing, a critical step in quality assurance processes.

Safety and Reliability

The tool's precision directly contributes to the safety and reliability of plastic products. By enabling accurate impact testing, manufacturers can predict how products will behave under stress, minimizing the risk of failure in real-world applications. This is crucial in environments where product failure can lead to safety hazards.

Broad Application Spectrum

Pacorr's Notch Cutter Motorized is just one piece of the extensive puzzle of plastic and polymer testing instruments. The company offers a wide array of testing equipment, including melt flow index testers, tensile testing machines, and environmental stress cracking resistance testers, among others. These instruments cover a broad spectrum of tests necessary for assessing the various properties of plastic materials.

The Notch Cutter Motorized is an essential tool for the plastic industry, enabling precise preparation of specimens for impact testing. Its significance goes beyond mere compliance with testing standards, impacting product safety, reliability, and quality assurance. Pacorr's commitment to providing high-quality testing instruments ensures that manufacturers have access to the tools needed to uphold the highest standards of product integrity. In an industry where precision equates to performance, the Notch Cutter Motorized is an invaluable asset.

Pacorr is the most prominent Notch Cutter-Motorized manufacturers and suppliers that has been offering the most accurate testing instruments for the plastic industries and ensure best quality assurance of the products. The manufacturers in the plastic industries need to ensure that they are able to produce high quality and high strength products. These products are to be used in different working environments in industries. As there are harsh working conditions industries including heavy impact forces and extreme working factors like temperature and pressure, it is essential that the plastic products have the essential endurance required to survive such harsh working conditions. The forces that act upon the plastic products can easily cause breakage of the products and causing them to fail completely which can be a great risk for the safety in the industries. This demands for through testing of strength of the products with great accuracy and precision. The IZOD/CHARPY Impact test is the most commonly used testing procedure for determining the endurance and strength of the plastics against the impact forces. This test determines the resistance that a specimen can offer against the fracture caused due to heavy impact forces. In order to ensure the best accuracy of the test results, the testing standards prescribe a certain dimension of the test specimen that must be prepared accordingly or it can compromise the accuracy of the data.

Pacorr’s Notch Cutter-Motorized is the best instrument to prepare specimen for IZOD/CHARPY impact testing with great precision. The instrument is very easy to operate and comes with a motorized mechanism. There is a japan made micrometer incorporated in the device for best accuracy of the measurements. The range of the device is from 0 to 25mm with a least count of 0.01mm. This instrument can help in conducting the impact test on plastics with a great accuracy.

- Motorized Operation.

- Depth Micrometer: “Mitutoyo”-JapanMake.

- Range: 0-25mm

- L.C:0.01mm

- Cutting Angle: 45deg.

- Paint: PowderCoating

- Power: 230 V AC, 1 Phase, 60Hz.

A Notch Cutter Motorized is a precision instrument used in the plastic industry to prepare specimens for Charpy and Izod impact tests. It allows for the accurate cutting of notches in test specimens, ensuring that the samples meet the necessary standards for impact testing.

Notch preparation is critical for impact tests like Charpy and Izod because the presence of a notch in a specimen concentrates stress, making it easier to initiate and propagate a crack. This process is essential for assessing the material's impact strength accurately. The precision of the notch directly affects the reliability of the test results.

Pacorr's Notch Cutter Motorized offers several key features, including motorized operation for consistent and precise cuts, a depth micrometer from Mitutoyo-Japan for unparalleled accuracy, a range of 0-25mm with a least count of 0.01mm, a cutting angle of 45 degrees, and a durable powder coating. These features ensure the tool's reliability and longevity in preparing specimens for impact testing.

While primarily designed for the plastic industry, the Notch Cutter Motorized's precision and adaptability make it potentially useful for preparing test specimens from other materials that require similar impact testing protocols. However, its primary application and calibration are tailored to the needs and standards of plastic testing.

Using a Notch Cutter Motorized ensures that test specimens are prepared with high precision, which is crucial for accurate impact testing. This accuracy helps manufacturers understand how their products will perform under stress, contributing to the development of safer and more reliable products. By predicting product behavior under impact, manufacturers can minimize the risk of failure in real-world applications, enhancing product safety and quality assurance.

Our Clients

A countless string of happy and satisfied customers vouch for our

excellence and complete quality control support.