Paint, Plating & Automotive Testing Instruments

Ensuring the quality, durability, and performance of paints, coatings, and plated surfaces is critical for industries worldwide. Pacorr is a trusted name in manufacturing and supplying Paint Testing Instruments, Plating Testing Instruments, and Automotive Testing Instruments, serving industries that demand high accuracy, repeatability, and compliance with international standards.

Our range of advanced testing equipment helps manufacturers evaluate surface coatings, measure critical parameters, and simulate real-world operating conditions to guarantee long-lasting performance. With a strong focus on precision, reliability, and compliance with ASTM, ISO, and BIS standards, Pacorr’s instruments are designed for both laboratories and production environments.

Why Surface Coating & Plating Testing is Essential

In modern manufacturing, coatings are more than aesthetics—they play a functional role in protecting substrates from corrosion, abrasions, weathering, and chemical attack. In industries like automotive, aerospace, appliances, and metal finishing, a minor defect in coating can lead to:

- Reduced product lifespan

- Warranty claims and returns

- Poor brand image

- Higher production costs due to rework

This is why systematic paint, coating, and plating testing has become a mandatory part of quality assurance and product validation.

Key Parameters Measured by Pacorr Instruments

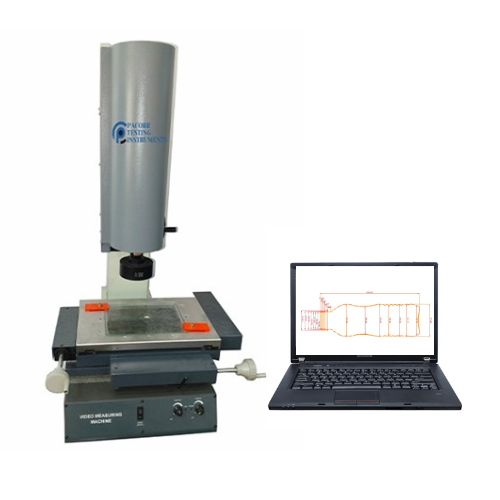

Pacorr’s testing instruments cover a wide range of surface quality evaluations, including:

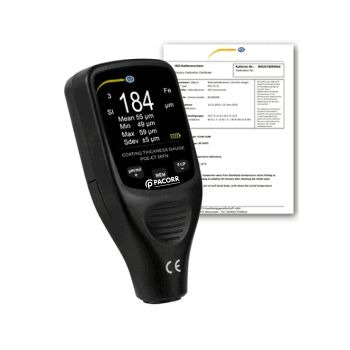

- Coating Thickness Measurement → Ensures uniformity of paint or plating layers.

- Gloss & Appearance Testing → Helps in maintaining surface appeal and customer satisfaction.

- Adhesion Strength (Cross Hatch / Pull-off Testing) → Determines how strongly coatings bond to substrates.

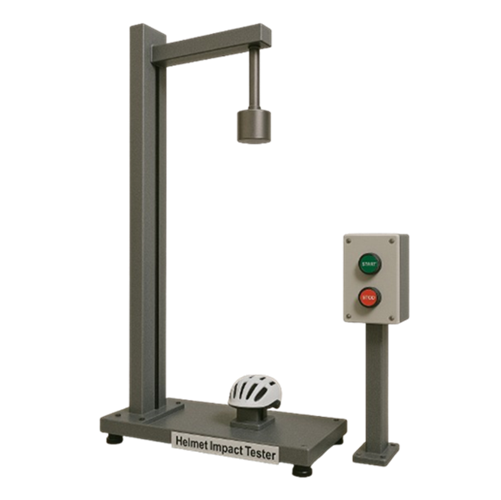

- Impact Resistance Testing → Evaluates a coating’s ability to withstand sudden forces.

- Salt Spray (Corrosion) Testing → Accelerated testing for corrosion resistance of coatings and plated parts.

- Environmental & Climatic Testing → Simulating UV, humidity, and thermal cycles for long-term stability.

These tests give manufacturers actionable insights into how their coatings will perform in different environments, ensuring compliance with domestic and international market requirements.

Applications Across Major Industries

Pacorr instruments are widely used across sectors where surface quality has a direct impact on performance and brand value:

- Automotive Industry → Testing paints, clear coats, and electroplated automotive parts.

- Aerospace & Defense → Ensuring high reliability against corrosion and weathering in harsh conditions.

- Paint & Powder Coating Industry → Quality assurance during R&D, production, and final inspection.

- Appliance Manufacturing → Testing coatings on washing machines, refrigerators, and consumer goods.

- Metal Finishing & Plating Industry → Confirming nickel, chromium, zinc, or powder-coated surfaces meet durability standards.

Advantages of Pacorr Testing Instruments

- Standard-Compliant: Meets ASTM, ISO, and BIS testing requirements.

- Accuracy & Repeatability: Ensures reliable results across R&D and large-scale production.

- Customizable Solutions: Tailored to industry-specific needs for better integration.

- Improved ROI: Reduces rework, failures, and warranty claims.

- Strong Support System: Technical consultation, calibration, and after-sales assistance.

Frequently Asked Questions (FAQs)

Q1. What are Paint, Plating & Automotive Testing Instruments used for?

They are used to evaluate coating performance by measuring factors like thickness, gloss, adhesion, durability, and corrosion resistance, ensuring products withstand long-term usage and environmental stresses.

Q2. Which industries commonly use these instruments?

Automotive, aerospace, coatings and paint manufacturing, consumer appliances, and metal finishing industries widely use these instruments for quality validation.

Q3. Why is coating and plating testing important in the automotive industry?

Automotive coatings ensure resistance to UV exposure, temperature fluctuations, moisture, and scratches. Systematic testing prevents premature failures and maintains product aesthetics and longevity.

Q4. What are the common types of tests performed?

Gloss measurement, thickness analysis, adhesion/pull-off testing, impact testing, corrosion (salt spray) testing, and accelerated weathering tests.

Q5. Does Pacorr provide industry-specific solutions?

Yes. Pacorr offers custom-built testing systems designed to address unique challenges in paint, plating, and automotive testing applications.

Q6. Are Pacorr testing instruments compliant with international standards?

Yes. All instruments are validated against ISO, ASTM, and BIS standards, ensuring credibility in domestic and global markets.

Q7. How do I choose the right instrument for my application?

It depends on the property you want to analyze. For example:

- Gloss testing → Use a Gloss Meter

- Adhesion testing → Use Cross Hatch or Pull-off Tester

- Corrosion resistance → Salt Spray Chamber

Pacorr’s technical experts can guide you in selecting the most suitable solution.

Q8. Where can I purchase Paint, Plating & Automotive Testing Instruments?

Pacorr is a leading global manufacturer and supplier of Paint Testing Instruments, Plating Testing Instruments, and Automotive Testing Instruments. We serve industries not only in India but also across Asia, Middle East, Europe, Africa, and Americas, delivering equipment that is robust, precise, and customizable.

All instruments are backed by technical support, calibration services, and after-sales assistance, ensuring long-term reliability. Whether you are a manufacturing facility, R&D lab, or quality inspection unit, Pacorr provides worldwide delivery and end-to-end support for your testing needs.

Recent Blogs

Enhance your understanding of testing and precise quality control indistinct applications with our

knowledge based articles coming from top editors of industry leaders.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)