Textile Testing Instruments

Fabrics play a crucial role in our everyday lives—whether in clothing, home furnishings, automotive, or industrial applications. From comfort and aesthetics to safety and durability, textiles directly impact consumer satisfaction.

To ensure quality, textile testing instruments are used worldwide to measure properties like strength, elasticity, colorfastness, and resistance. This guarantees that fabrics meet both international standards and consumer requirements.

Why is Fabric Testing Important?

Before entering the market, every textile product undergoes testing because:

- Fabrics affect look, feel, and performance.

- Some fabrics can cause skin irritation or odors.

- Testing prevents customer dissatisfaction, product recalls, and compliance issues.

- It is essential for quality control, research, and new product development.

By using advanced textile testing instruments, manufacturers can ensure reliability, durability, and safety across different use cases.

Types of Textile Testing Instruments

Textile testing machines are classified based on static and dynamic properties:

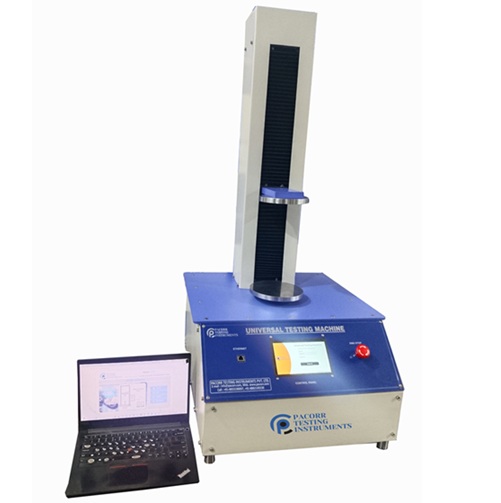

Static Testing Instruments

- Measure strength under fixed/static load.

- Example: Tensile Strength Tester

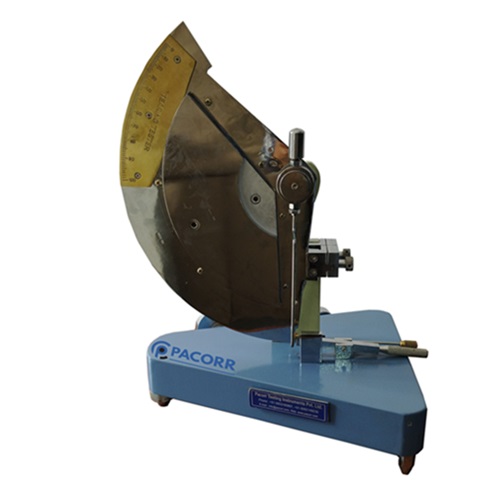

Dynamic Testing Instruments

- Measure performance under varying/dynamic conditions.

- Example: Shear Tester

Other popular testing solutions include:

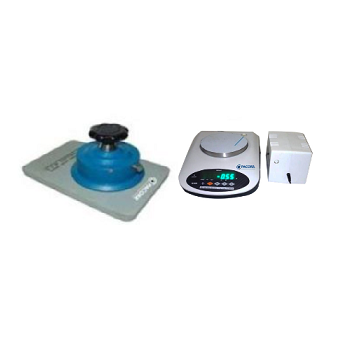

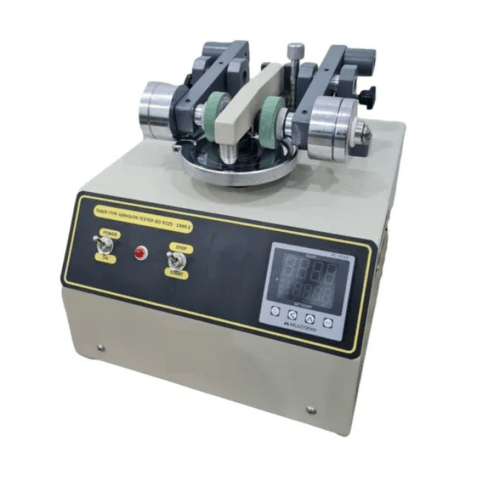

- Martindale Abrasion Tester – checks fabric durability & wear resistance.

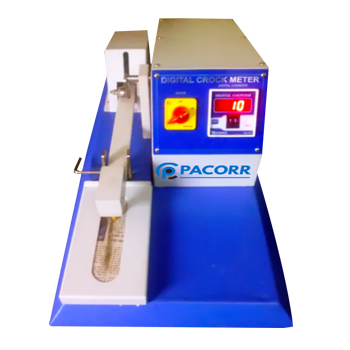

- Crockmeter Rubbing Fastness Tester – evaluates colorfastness against rubbing.

- Motorized Wrap Reel – measures yarn strength and performance.

Benefits of Using Textile Testing Instruments

- Quick Issue Detection – Early problem identification saves cost & time.

- Assurance of Quality – Helps manufacturers maintain specifications.

- Compliance to Standards – Ensures adherence to ISO, ASTM, AATCC norms.

- Improves Brand Reliability – Builds customer trust and reduces returns.

- Supports R&D – Helps in new product design and innovation.

Pacorr Testing Instruments – Trusted Industry Partner

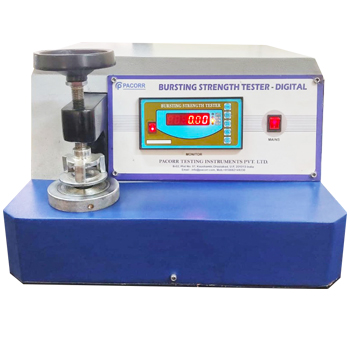

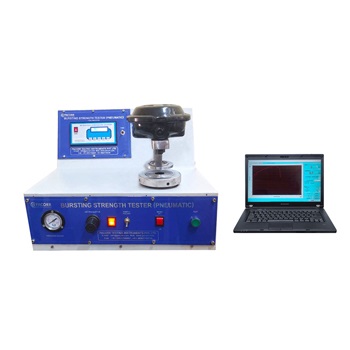

Pacorr Testing Instruments offers a wide range of international standard textile testing equipment designed for accuracy and durability. Their machines are user-friendly, compliant with ISO/ASTM/AATCC standards, and widely used across:

- Fashion & Apparel Industry

- Home Textiles

- Industrial & Technical Textiles

- Automotive Interiors

- Medical Textiles

Key Features of Pacorr Equipment:

- High-quality construction for long-term use

- Accuracy & repeatability for testing

- Customization options for specific industry needs

- Compliance with export-level certifications

Pacorr Textile Testing Instruments – Quick Overview

| Aspect | Detail |

| Objective | Ensuring textile quality, safety & durability |

| Key Instruments | Martindale Abrasion Tester, Rubbing Fastness Tester, Wrap Reel |

| Benefits | Precise results, 100% Quality Control, Safety assurance |

| Target Audience | Textile manufacturers, R&D labs, Quality Assurance teams |

| Provider | Pacorr Testing Instruments |

FAQ's

Q1. What are Textile Testing Instruments used for?

Textile Testing Instruments measure and evaluate textile quality, strength, durability, and performance. They help in detecting manufacturing defects, ensuring compliance, and improving overall product reliability.

Q2. Which industries require textile testing equipment?

Industries such as fashion, home furnishings, technical textiles, automotive, medical, and industrial fabrics rely on textile testing to ensure product safety and functionality.

Q3. What tests can textile testing instruments perform?

They perform tensile strength, tear strength, pilling resistance, shrinkage, seam slippage, and colorfastness tests to simulate real-life use conditions.

Q4. Why is fabric testing critical in manufacturing?

Because it ensures consumer safety, compliance with international regulations, and product consistency, while reducing returns and recalls.

Q5. Does Pacorr provide customized solutions?

Yes, Pacorr offers custom-designed testing instruments tailored to specific fabrics and industry requirements.

Q6. Are Pacorr machines globally compliant?

Yes, all equipment is built as per ISO, ASTM, and AATCC standards, making them reliable for both domestic and export markets.

Q7. Where can I buy reliable Textile Testing Instruments worldwide?

Pacorr is a trusted global provider of advanced Textile Testing Instruments, supplying precision-engineered equipment to manufacturers, research labs, and quality control facilities across the world. With a strong focus on accuracy, compliance with international standards (ISO, ASTM, AATCC), and customer support, Pacorr ensures that its machines meet the diverse needs of industries ranging from fashion and apparel to technical and industrial textiles. Whether you are located in Asia, Europe, North America, or the Middle East, Pacorr delivers both standard and customized solutions with the same commitment to quality, durability, and reliability—making them a preferred partner for textile companies worldwide.

Conclusion

Textile testing is not just a step—it is the backbone of quality assurance, safety, and innovation in the textile industry. By leveraging advanced machines from Pacorr Testing Instruments, manufacturers can stay compliant with global standards, improve customer trust, and achieve excellence in production.

Recent Blogs

Enhance your understanding of testing and precise quality control indistinct applications with our

knowledge based articles coming from top editors of industry leaders.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)

.jpg)

.jpg)