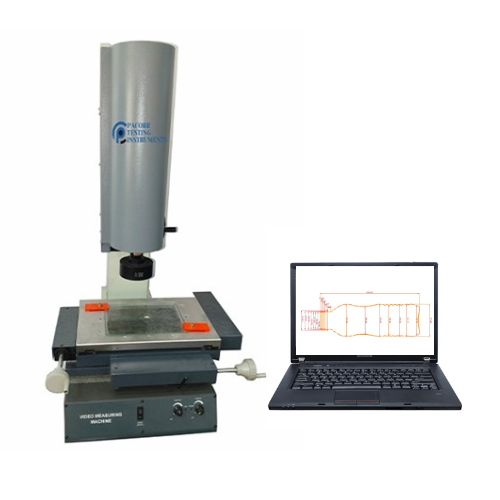

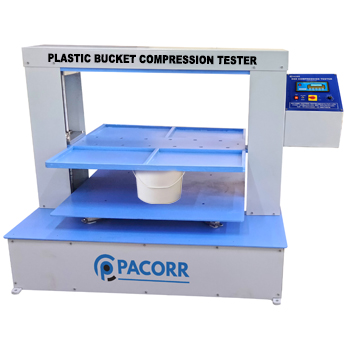

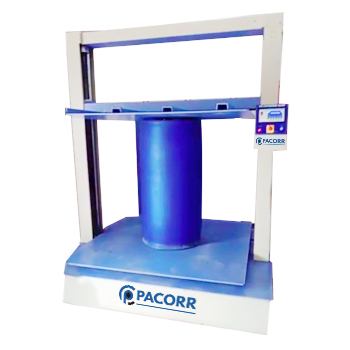

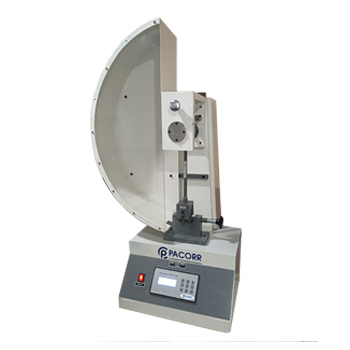

Plastic & Polymer Testing Instruments

Advanced Solutions for Reliable Plastic & Polymer Quality Testing

Pacorr is a leading manufacturer and supplier of Plastic & Polymer Testing Instruments in India, trusted by industries worldwide for delivering accurate, reliable, and standard-compliant testing solutions. Our advanced testing equipment is designed to meet the latest industry demands and global quality standards such as ASTM, ISO, and DIN.

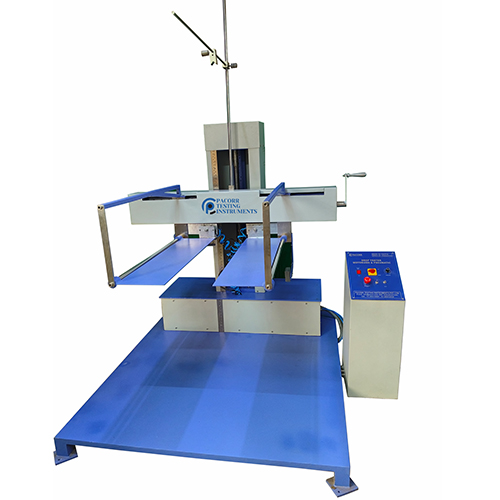

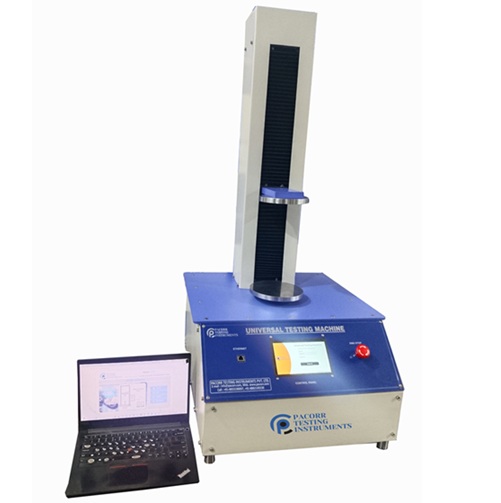

With a diverse portfolio of precision-engineered instruments, Pacorr helps manufacturers test the physical, mechanical, and chemical properties of plastic and polymer materials with unmatched accuracy. From tensile strength, melt flow rate, impact resistance, hardness testing, to thermal analysis, our instruments ensure product consistency, safety, and durability.

Industries including automotive, packaging, construction, consumer goods, and electronics rely on Pacorr to validate raw materials and finished components. Every instrument is built to streamline R&D, enhance production efficiency, reduce product failures, and support export compliance.

Whether you are testing polymer granules, flexible films, injection-molded parts, or finished plastic products, Pacorr delivers the right solution to ensure your materials meet both national and international standards.

Why Choose Pacorr for Plastic & Polymer Testing Equipment?

- ISO and CE Certified Manufacturer – Assuring global credibility

- Compliant with ASTM, ISO and DIN Standards – Results accepted worldwide

- Custom-Built Instruments – Tailored for specific industry needs

- Trusted by Leading Brands – Serving automotive, FMCG, pharma and packaging industries

- Global Reach with Local Support – Serving India and international markets with after-sales service

With over 25 years of expertise, Pacorr has become the preferred choice for quality testing instruments across industries.

Key Tests Performed by Plastic & Polymer Testing Instruments

- Tensile Strength Testing – Measure load-bearing capacity

- Melt Flow Rate Analysis (MFR) – Evaluate processing behavior of polymers

- Impact Resistance Testing – Assess toughness against sudden shocks

- Hardness Testing – Check rigidity and resistance

- Thermal Deformation Testing – Analyze heat endurance and performance stability

FAQs – Plastic & Polymer Testing Instruments

Q1. What are Plastic & Polymer Testing Instruments used for?

Plastic & Polymer Testing Instruments are used to analyze strength, durability, flexibility, melt flow, and resistance properties of plastic materials. They ensure materials meet safety, quality, and performance standards, reducing risks of failure in real-world applications.

Q2. Which industries require plastic and polymer testing equipment?

Industries such as automotive, packaging, construction, electronics, and medical devices rely heavily on testing equipment. For example, in automotive, plastics must withstand stress and heat, while in packaging, films must resist tearing and impact.

Q3. What types of tests can be performed?

Pacorr instruments perform tests like tensile, impact, melt flow rate, hardness, and thermal stability to determine how plastics behave under real conditions.

Q4. Why is polymer testing important in product development?

Polymer testing ensures manufacturers select the right material grade, prevent failures, reduce recalls, and comply with regulations, ultimately speeding up product launch.

Q5. Does Pacorr provide customized testing solutions?

Yes. Pacorr designs customized plastic testing instruments tailored to specific applications, ensuring maximum accuracy and efficiency.

Q6. Are Pacorr instruments compliant with global standards?

Yes. Every instrument is built in line with ASTM, ISO, and DIN standards, ensuring internationally accepted test results.

Q7. How do I choose the right testing instrument?

Choice depends on material type, test requirements, and industry needs. Pacorr experts help businesses select the most efficient equipment.

Q8. Where can I buy high-quality plastic testing instruments in India and worldwide?

Pacorr is one of the top manufacturers in India, offering reliable machines with expert after-sales support. Along with serving Indian industries, Pacorr also supplies its testing instruments globally, ensuring world-class quality and compliance with international standards.

Pacorr Plastic & Polymer Testing Instruments are built for businesses that want to ensure product quality, achieve global compliance, and boost manufacturing efficiency. By combining accuracy, standard compliance, and customization, Pacorr stands out as the go-to partner for plastic testing solutions in India and abroad.

Recent Blogs

Enhance your understanding of testing and precise quality control indistinct applications with our

knowledge based articles coming from top editors of industry leaders.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)

.jpg)