PET Bottle and Preform Testing Instruments

PET bottle and preform testing instrument is a crucial tool in ensuring the quality, durability, and performance of PET bottles and preforms used in various industries such as beverages, pharmaceuticals, cosmetics, and household products. With growing demands for packaging that meets both functionality and regulatory standards, these instruments play a pivotal role in maintaining product integrity and customer satisfaction.

PET bottles and preforms must undergo rigorous testing to validate their mechanical properties, dimensional accuracy, and resistance to external factors. Testing parameters such as tensile strength, compression resistance, wall thickness uniformity, and impact strength are critical to ensure these packaging solutions can withstand real-world conditions. A PET bottle and preform testing instrument is designed to deliver precise and reliable results for these essential parameters.

One of the key benefits of using a PET bottle and preform testing instrument is its ability to detect flaws or inconsistencies during the manufacturing process. From evaluating the transparency and clarity of the material to measuring its resistance to leakage and deformation, these instruments provide manufacturers with actionable insights. This not only improves production efficiency but also reduces wastage and rejects.

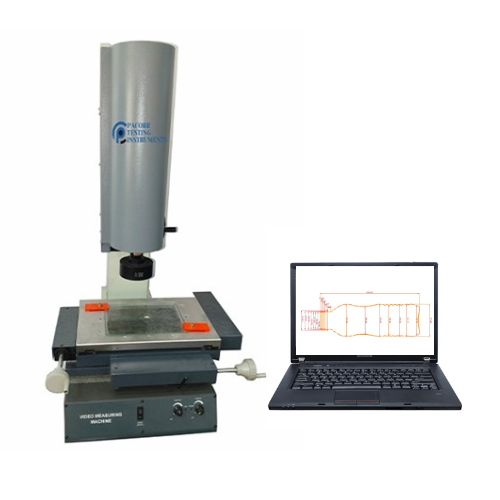

Additionally, advanced PET bottle and preform testing instruments are equipped with user-friendly interfaces, automation capabilities, and data recording features, making them indispensable for quality assurance teams. Their versatile design allows for testing a wide range of preforms and bottle sizes, ensuring compatibility with different production lines.

For industries aiming to meet international quality standards such as ISO and ASTM, PET bottle and preform testing instruments are an essential investment. They help manufacturers demonstrate compliance with stringent regulatory requirements, bolster customer confidence, and gain a competitive edge in the market.

By integrating PET bottle and preform testing instruments into your quality control processes, you can achieve consistent product excellence, enhance sustainability, and ensure your packaging meets the evolving demands of modern consumers.

FAQ's

Q1. What is the purpose of using bottle testing instruments in manufacturing?

A. Bottle testing instruments are critical tools in the manufacturing industry for evaluating the strength, durability, and quality of both PET and glass bottles. These machines help ensure that each container can withstand various stress factors such as internal pressure, external load, and impact during transportation or storage. By performing these tests, manufacturers can identify structural weaknesses, reduce product recalls, and maintain consistent packaging standards. This not only helps in meeting industry-specific quality norms but also protects brand reputation by minimizing chances of leakage or breakage. Ensuring the quality of bottles also supports cost-efficiency in large-scale production lines.

Q2. Which industries commonly rely on PET and glass bottle testing equipment?

A. Several industries use PET and glass bottle testing equipment as part of their quality assurance processes. The most common sectors include food and beverage manufacturing, pharmaceuticals, cosmetics, and chemical packaging. In these industries, packaging plays a vital role in maintaining product integrity, especially when products need to be transported over long distances or stored under various environmental conditions. High-quality testing instruments help companies meet international compliance standards and ensure that every bottle is fit for purpose. Without rigorous testing, packaging failures could lead to customer dissatisfaction or even safety risks, which is why these tools are essential.

Q3. What types of bottle testing machines does Pacorr offer for PET and glass containers?

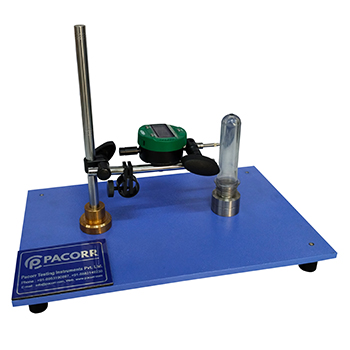

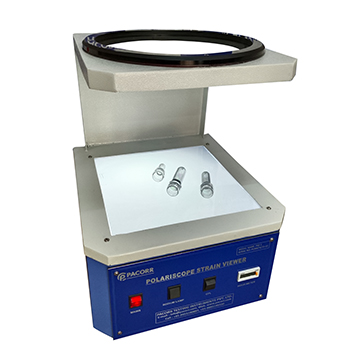

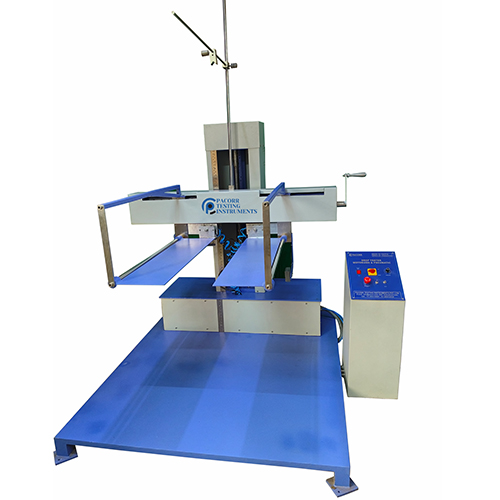

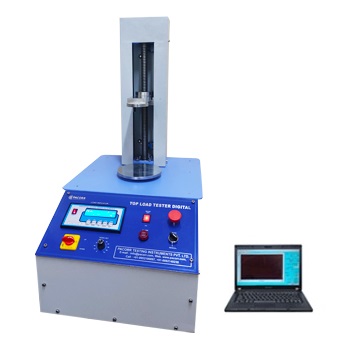

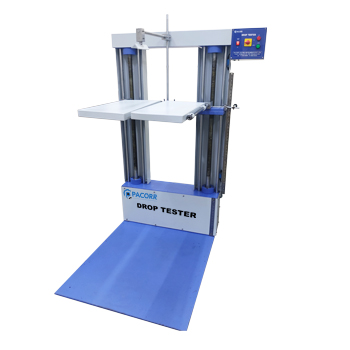

A. Pacorr provides a comprehensive selection of advanced testing instruments tailored for both PET and glass bottles. The range includes top load testers to assess vertical strength, burst testers for checking internal pressure tolerance, torque testers for cap tightness, vacuum leak testers for seal integrity, and section weight analyzers for material distribution. Each machine is designed to deliver precise results and help manufacturers maintain high quality control standards. These instruments play a vital role in production lines where consistency and accuracy are non-negotiable. Pacorr’s solutions are trusted across industries due to their reliability, ease of use, and compliance with testing standards.

Q4. Why is quality testing important for PET and glass bottles before product filling?

A. Testing PET and glass bottles before filling them with product is crucial because it directly affects the safety, efficiency, and shelf-life of the final goods. If the bottles are not tested, issues like weak structure, improper sealing, or unequal weight distribution may go unnoticed, leading to product leaks or contamination. In mass production, even a small error in packaging can escalate into significant losses. Pre-filling testing ensures every container meets performance criteria under different pressure and temperature conditions. It helps businesses avoid customer complaints, reduce product waste, and strengthen quality assurance protocols that support regulatory compliance and brand trust.

Q5. Can Pacorr customize bottle testing instruments to meet unique production needs?

A. Yes, Pacorr specializes in providing customized bottle testing instruments that are specifically tailored to match the unique needs of different production environments. Whether you are working with PET bottles that require precision torque control or glass containers that need impact resistance analysis, Pacorr’s team can engineer equipment based on your technical specifications. Custom solutions help businesses optimize their testing workflows and adapt to the specific dimensions, material properties, or quality benchmarks of their packaging line. These tailored machines not only enhance testing accuracy but also increase efficiency and reduce downtime across manufacturing operations.

Q6. Are Pacorr’s testing instruments compliant with international quality standards?

A. All bottle testing instruments manufactured by Pacorr are built to meet internationally recognized quality and performance standards. Whether you are operating under ISO, ASTM, or industry-specific guidelines, these instruments are designed to deliver accurate and reliable test results that comply with global benchmarks. This ensures consistency across different batches and aligns with the requirements of multinational clients who demand certified quality control processes. By adhering to such standards, Pacorr helps manufacturers demonstrate credibility in international markets while also ensuring internal quality management systems are up to date and audit-ready.

Q7. How does PET bottle testing differ from glass bottle testing?

A. While both PET and glass bottles require rigorous testing, the methods and focus areas differ due to the materials’ physical properties. PET bottles are lightweight and more flexible, so tests typically focus on top load strength, burst resistance, and torque performance to evaluate sealing integrity. In contrast, glass bottles are more rigid and fragile, requiring testing for impact resistance, thermal shock tolerance, and vertical load-bearing capacity. Each material poses unique challenges, and the testing instruments used must be capable of detecting flaws specific to the type of packaging. Choosing the correct test method ensures the container’s safety and durability in real-world usage.

Q8. How do I choose the right testing equipment for my bottle packaging line?

A. Selecting the right testing equipment depends on several factors, including the type of bottle material (PET or glass), the nature of the product being packaged, and specific quality standards your industry must meet. For instance, a beverage manufacturer might prioritize burst strength, while a pharmaceutical brand might focus on seal integrity. Pacorr offers expert consultation to help clients identify which instruments suit their production needs best. By evaluating your testing objectives, product specifications, and production volume, the right equipment can be recommended to streamline quality assurance and ensure product safety throughout the supply chain.

Q9. Where can I find a reliable supplier of bottle testing equipment in India?

A. Pacorr is one of the leading suppliers and manufacturers of high-performance bottle testing instruments in India. With a proven track record of delivering reliable, industry-compliant machines, Pacorr serves clients across sectors like food, beverages, pharmaceuticals, and cosmetics. The company provides both standard and customized solutions for PET and glass bottle testing, ensuring each piece of equipment is engineered to meet real-world quality challenges. From product guidance to after-sales support, Pacorr stands out as a trusted partner for businesses looking to upgrade their quality control processes with precision-engineered testing instruments.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)

.jpg)